Shortly before the Round the Island Race, one of the largest yacht races in the world, it’s all go at the T Sails loft in Southampton with sailmaker Tim Scarisbrick…

PBO Project Boat

Shore power: solving tripping problems

Ali Wood gets a crash course in reverse polarity and smart charging when Project Boat Maximus’s shore power gets trippy

Sail design – using 3D software and laser technology to cut new sails

During the survey of our Maxi 84, the PBO Project Boat Maximus, we were warned by a marine surveyor that there was only so much he could tell us about…

How to measure your yacht for new sails

Measuring your boat for new sails is a job for the sailmaker, so when our PBO Project Boat Maximus needed new sails, we called in sailmaker Daryl Morgan, technical manager…

Restoring a vintage Sailor radio

Ali Wood’s Sailor radio is given the VIP treatment

Seajet Bioclean silicone antifoul review: Our verdict after one year on the water

Does silicone antifouling work? It’s not flying off the shelves yet, according to suppliers, but the results from our Project Boat are promising. In fact, in the words of the…

Securing mast cable on our Maxi 84

With the help of ACM Marine, Ali Wood goes about securing mast cable on the Maxi 84 PBO project boat

Family sailing safety gear: TESTED!

Ali Wood discusses the sailing safety gear she chose for their first family cruise on board their Maxi 84, and how it performed

Marine alternator troubleshooting

Ali Wood gets to grips with Maximus’s faulty electrical system after some unexpected failures made an appearance on passage

Refurbishing a boat alternator

James Wood removes Maximus’s alternator and gets it repaired

How to make rope: The modern factory method explained

Running rigging is something you tend to take for granted… until it fails, which is what happened during the boat test of Maximus, our Maxi 84 Project Boat. Fortunately, thanks…

Maxi 84: roomy, capable & rewarding to sail

Why has the Maxi 84 proved so popular since her launch 45 years ago? David Harding sailed Maximus, the ‘work in progress’ refurbished PBO Project Boat, to find out

Replacing a rotten companionway step

James Wood gets to grips with epoxy when repairing a rotten step support on Maximus's companionway

Choosing a marine toilet for the PBO Project Boat

Choosing a marine toilet isn’t as straightforward as you think – and after looking at the options it may be that refurbishment rather than replacement could be the answer. With…

How to service a marine diesel engine in 12 simple steps

It was time to service the marine diesel engine on our Maxi 84 cruiser. Knowing how to diagnose and fix engine faults is a useful skill for any boat owner,…

How Perkins marine engines became world-famous

The Volvo Penta engine on our Maxi 84 Maximus is a re-badged version of the Perkins 103-06, itself originally imported from a Japanese company called Ishikawajima Shibaura Machinery. Perkins marketed…

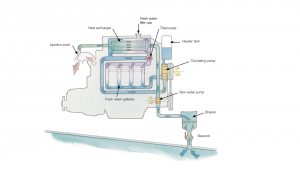

How an intercooled engine works

With an inter-cooled engine, the role of the seawater is to take away the heat from the freshwater. The seawater, or ‘raw water’, is a separate flow to the fresh…

Sea toilet restoration: How I refurbished the heads on the PBO Project Boat

With seacocks previously installed in the Maxi 84, it was time to connect the hoses. The first thing to decide was what sort of installation. As Ali explained in her…

Maximus sets sail – Chichester to Poole shakedown

The day was finally here; time to take Maximus, our Maxi 84, from Chichester Marina to her new home in Poole. After many sleepless nights, last-minute trips to Force 4…

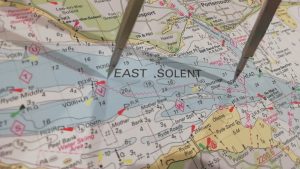

Passing planning for a shakedown voyage

With Maximus, our PBO Project boat ready for her shakedown voyage from Chichester to Poole, I turned my attention to passage planning. I dug out my old logbook and realised…