Ali Wood gets to grips with Maximus’s faulty electrical system after some unexpected failures made an appearance on passage

While motoring from Yarmouth to Poole with my husband, James, and friend Gilbert Park, something strange happened.

The rev counter on our Maxi 84 dropped to zero, yet the engine, a Volvo Penta MD2020, was still running. There was no drop in speed.

Coincidentally, the tiller pilot stopped too, but that – like the fuel starvation issue we’d had the day before – was unrelated.

Ah well, this was, after all, a ‘shakedown’ voyage to highlight any possible problems.

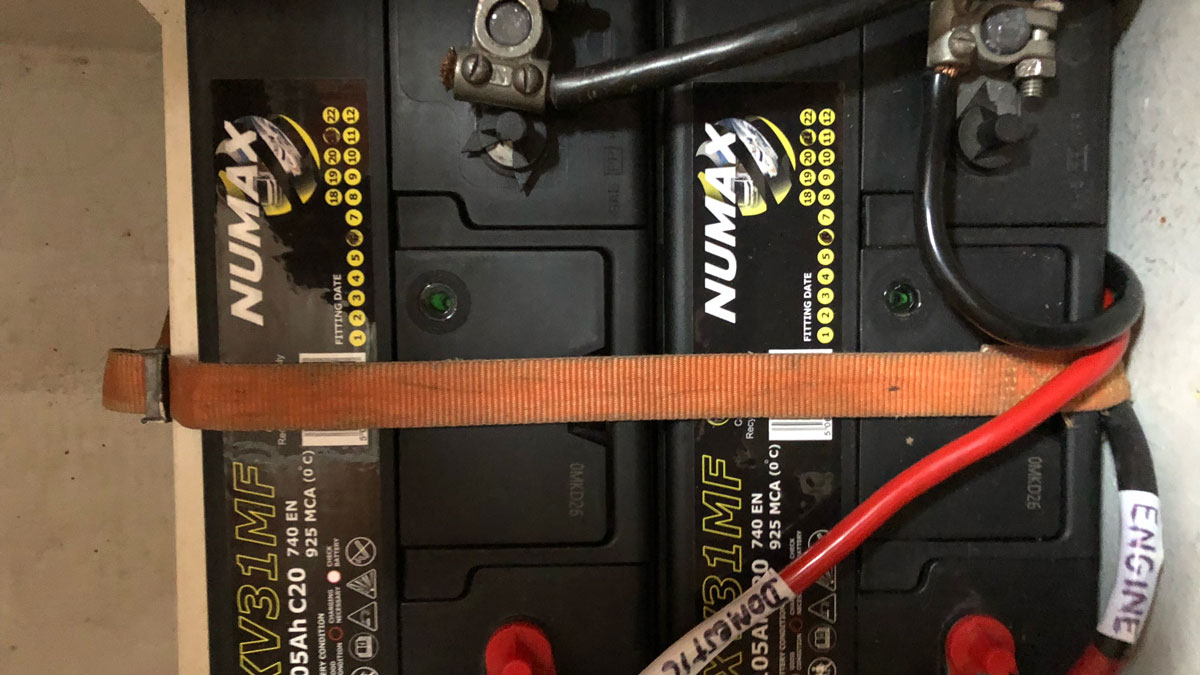

12.44V is getting a bit low

Gilbert suspected the alternator might be at fault, and this was further confirmed when we saw the battery voltage on the Victron monitor had dropped from 13.4V to 12.7V – not what you’d expect if the marine alternator was happily topping up the batteries.

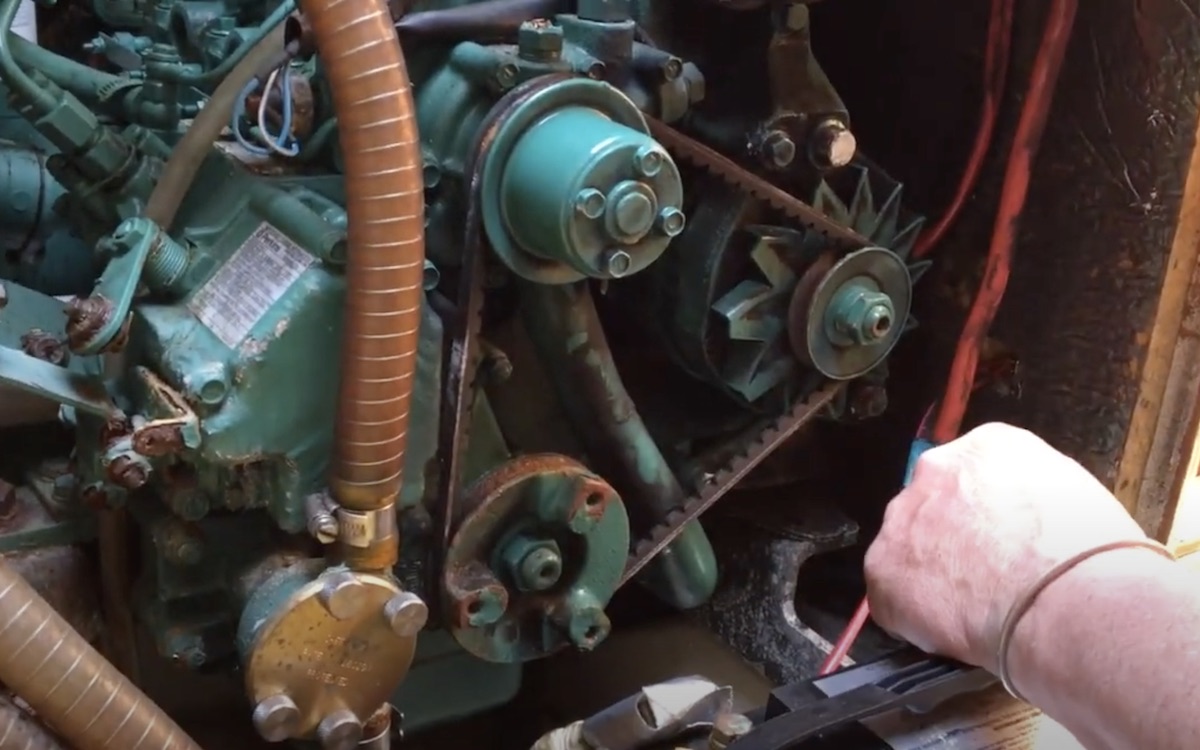

The marine diesel engine was in good condition, and we’d recently replaced the alternator belt during a service.

A quick visual inspection showed it was turning nicely, along with the marine alternator itself. We switched off all unnecessary electronics and motored to Cobb’s Quay Marina in Poole, Maximus’s new home.

On plugging in to shore power, the battery charge crept back up, supporting Gilbert’s theory that it was the marine alternator.

Ground return system showing only the starting, charging and monitoring circuits. In reality the engine circuitry is much more complicated. Credit: RYA Diesel Engine Handbook

Before consulting the experts, I first wanted to understand how the alternator works, and for this, I turned to the RYA Diesel Engine Handbook, written by longtime PBO contributor, Andrew Simpson.

He explains that to function, a boat’s DC (direct current) system must form a circuit, requiring a power source (ie the battery) and an electrical load (ie a lightbulb).

The current flows from the positive terminal of the battery along one side of the circuit, lights the bulb and flows back down the other side to the negative terminal.

Boat engine installations have ‘earth (or ground) return’ circuits, where the positive ‘live’ feed for each load travels along individual electrical cables, and normally the negative terminal of the battery is connected to the engine block via a heavy duty wire to complete the circuit.

The engine was still running properly but the rev counter was at zero

The starter motor, alternator, oil pressure and temperature sensors are all attached directly to the engine and are therefore earthed through their casings to the negative side of the battery.

However, some of the Volvo Penta engines have negative earth isolation systems where the negative from the starter motor and alternator go ‘direct’ to the batteries, and relays are used to temporarily earth the engine block to energise glow plugs, engine stop solenoids etc, and sensors are wired positive and negative.

This is to protect systems such as aluminium saildrives and gearboxes from galvanic corrosion.

A negative wire – also fairly heavy – will run from the negative system to the distribution (switch) panel, controlling the boat’s various lights and appliances.

How does a marine alternator work?

The marine alternator fitted to Maximus’s Volvo Penta MD2020 engine is a 60Ah Valeo alternator, which is more than ample to keep up with the loads of a small boat such as the Maxi 84.

It’s a compact device in which a magnetised rotor spins within a magnetic field.

The spinning is powered by a V-belt from an engine pulley. Its purpose is to generate electrical power to top up the batteries.

But as Andrew points out, ‘batteries are like savings accounts. You can only draw out what’s already been put in.’

Using a multimeter to check a fuse is actually working – sometimes it’s difficult to tell just by looking

Hence, a working alternator is pretty essential!

When Maximus is alongside, she can hook up to her shore powered battery charger, a Victron Phoenix IP43, which converts the mains AC input to DC, and can be monitored and controlled via Bluetooth.

However, once away from her berth, she’s dependent not only on the propulsion generated by the engine, but the electrical power too.

If there’s no electrical power, then we wouldn’t have the voltage required to start the engine or use the instruments.

Batteries deliver and are charged by DC currents, but alternators, as the name suggests, produce ‘alternating currents’ (AC), so these need to be converted to DC before use.

This process, known as ‘rectification’, is accomplished by a nest of diodes built into the alternator. Another key part of the circuitry is the regulator, which controls the charge voltage to the batteries.

Why did the rev counter stop working?

I was puzzled as to why the rev counter falling back to zero should mean there was an alternator problem.

On my next visit to the boat I called engine expert Stu Davies, who happened to be on his boat in Portugal. As ever, he was happy to help.

He explained that the alternator starts working when you turn the ignition key on the panel in the cockpit.

This switches on the ignition light, which allows voltage to the alternator exitation circuit.

This black cable for the wiring loom was rattling loose

The alternator then starts producing AC voltage which is rectified to produce DC voltage.

The rev counter then drives off the AC cycles and calculates the number of revolutions from that.

If the rev counter starts dropping, or doesn’t work at all, it means it’s not getting a feed from the alternator.

The first thing to check, Stu advised, would be the relays and fuses attached to the engine.

Continues below…

I need help understanding my marine alternator! Ask the experts

PBO reader Paul Farr wants help in understanding his marine alternator. Engine whisperer Stu Davies comes to his aid

Sailing without an engine: How I jury rigged an alternative

When wind and batteries fail Genevieve Leaper is becalmed without an engine, but she jury rigs an alternative means of…

How the diesel engine works – take a look at Maximus’s Volvo saildrive

Checking the diesel engine after a long lay-up is an essential task before launching any boat, says marine surveyor Ben…

How to service a marine diesel engine in 12 simple steps

It was time to service the marine diesel engine on our Maxi 84 cruiser. Knowing how to diagnose and fix…

I therefore removed the plastic lid of the relay box and gave the wires a bit of a wiggle to see if they were loose in any way, but they felt sound and secure.

I also noticed one of the fuses had blown in the fuse box, but as there were three others and one was on line Stu said this shouldn’t be a problem.

Volvo Penta fit spare ones in the fuse box for just such an eventuality – simply move the jumper to the next one if one fails.

After finishing my call, I ran my hands over the other parts of the engine and gave the loom a shake. It appeared to be loose. Could this be the problem?

A fuse had blown but it wasn’t affecting the alternator

As our marine electrician, Adam of ACM Marine, was due to visit the following day, I decided to ask him to take a look.

Adam agreed the loom was indeed loose. It had been secured during Maximus’s rewire, but as it led back through a locker full of ropes and fenders, into the engine control panel, it could have worked its way free.

“It’s possible that if there was resistance there it wasn’t creating the electrical field it needed to tell the alternator to switch on,” said Adam, echoing Stu’s words. “Alternators need to build a magnetic field so what you do is give it a flash with the revs to get it to kick into life. Sometimes it helps to give a few more revs.”

Unfortunately, when we switched the engine back on, the tightened loom made no difference. The alternator still wasn’t working.

Testing the marine alternator

With his multimeter, Adam checked the output of the marine alternator and confirmed there was no voltage.

“You’re going to need to get the alternator off and get it bench tested,” he said. “Hopefully the alternator is the problem, and not the loom. There’s a module behind there that’s a Volvo part and really expensive – £400 to £500. They can get rusty and affect the alternator.

On the other hand, a new alternator is around £100 and around £50 to repair, so that’s your first step.

Marine electrician Adam McMenemy explains and demonstrates how to use a multimeter

Hopefully some water just got in and popped the diodes.” I asked why the alternator would have worked initially, and then failed, and Adam reminded me that when we took on the boat the engine bay had been soaked by a leak through the companionway.

In fact, he’d made me promise to sort out the leaks before he even touched any boat electrics! There had been a lot of damp rotten wood around.

If any water had got into the alternator it might have damaged the diodes, which are very sensitive.

Furthermore, if the engine was stalling, as it had been on the first day of our voyage, due to the fuel valve vibrating closed, the alternator would have been speeding up and slowing down, which wouldn’t have helped.

“Alternators do just pack up from time to time, but it’s not a common issue,” said Adam. “Once it’s fixed or replaced it shouldn’t happen again.”

Stages of battery charging

With the marine alternator not working, Adam warned that we shouldn’t let the battery drop below 12V, and explained there are three different stages to charging a lead acid battery:

- Bulk (or constant-current charge) is where the battery charges at a constant to about 70%, taking around 5-8 hours

- Exhaustion (or topping charge) is where the remaining 30% is filled more slowly, over 7-10 hours. This is essential for the health of the battery.

- Float charge is the final stage, where the batteries are maintained at a set lower level to compensate for the self-discharge that all lead-acid batteries suffer.

This helped me understand why, when charging from the alternator, we’d seen the batteries climb as high as 14.5V and then at other times – for example, when returning to the boat after leaving shore power connected – the monitor would read around 13.4V.

A multimeter was essentially for troubleshooting the problem

If left unplugged, which we do for several weeks to ‘exercise’ the batteries, voltage will drop to around 12.4V.

“If you’re sitting around on a mooring, anything between 12.4V and 12.8V is fine,” said Adam. “Anything 13.6V or above is classed as a charge. 14V to 14.7V is really good charging. If you put the engine on, and the alternator is working properly, you’d expect 14V or above.”

On Adam’s advice, I asked around and found a local man who serviced alternators and starter motors.

The good news: he would take a look for no fee, and only charge us if he could fix it.

The bad news: he wouldn’t come to the boat. We had to remove it ourselves. That was easier said than done!

Removing the alternator proved to be a two-man job, so at this stage I called in my husband, James.

While Adam was on the boat, I also asked him to look at the ‘broken’ tiller pilot.

As the light wasn’t on at the switch panel, the most obvious cause was that we’d blown a fuse, and on closer inspection we could see that was the case. The wire inside was black and burned through.

Fun with fuses

“There was a 5A fuse in there, but it was obviously borderline, so we’ll go up to a 7.5A,” said Adam, taking it out, and rummaging through his box of electrical bits and pieces.

I asked why not go up to a bigger fuse in the first place? Adam said it depends on the rating of the instrument.

The point of the fuse is to protect the wiring and item from damage and a dead short.

Looking for the correct size of fuse

“If I put a 20A fuse in there it would be OK for the cable, which is rated 30A, but if the tiller pilot is, say, 7.5A then it’s not protected,” he explained.

“You should rate the fuse to the item and run the correct size cable to cope with running it. If it was a light for example, and you didn’t have a low enough fuse, then nasty things could happen. It could catch fire. The fuse is there to stop that and will pop when the current goes higher than the fuse value.”

Adam also pointed out that glass fuses come in different lengths.

You get some which are standard, some half the length, and others only marginally shorter than standard.

The standard and slightly shorter ones are so close you may think you’ve got the right one, because the fuse holders allow it to fit – but it won’t work in some switch panels.

Blackened and burned-through fuse

“You can find yourself chasing a fault that’s not there; it’s just that the fuse isn’t actually big enough,” said Adam.

When it comes to spares, Adam suggests buying a multipack ranging from 1A to 15A. If you need to replace a specific fuse, take the blown one to the chandler to be sure you have the correct replacement.

During our boat survey, our marine surveyor used a multimeter to conclude that Maximus’s batteries were dead.

And now Adam had demonstrated that there was no output from the tiller pilot fuse and the marine alternator.

It had been a long time since I’d used a multimeter – probably in school science – so I asked for a demonstration.

Multimeter demo

Among other things, a multimeter measures resistance – or opposition – in a circuit. If an item’s working it will create resistance.

If it’s dead, it won’t. The multimeter works by injecting a small current into the circuit and measuring the voltage drop across various points.

The known current, and resulting voltage drop, are then used to calculate resistance using Ohm’s Law.

Multimeter probe checks current to the alternator from the ignition switch

To demonstrate, Adam put the multimeter probes together. The meter beeped and showed a measurement of 0.3 Ohm; showing resistance between the two wires.

Next he put the leads either side of the blown fuse, and as expected, the meter was silent and showed zero resistance. In other words, the circuit was left open.

“When it comes to fault finding you can do the same thing with a cable,” said Adam. “Start one end of the cable and move along. If it’s reading 0.3 Ohm you know the cable’s good. If it comes up with nothing, either it’s not the right cable or it’s broken. If the Ohm reading goes up really high, it means there’s a lot of resistance. This could be corrosion in the circuit or that the cable’s rusted out or gone wrong. This happens quite often with mast cables; they go black or corroded, meaning there’s resistance and quite often you get a volt drop from one end of the cable to the other.”

An interesting voyage

Our two-day trip from Chichester to Poole had thrown up some interesting conundrums, but I was glad to have solved them – if not yet fixed them.

It had been a eye-opening voyage; full of dropping revs and voltage – neither of which I’d paid much attention to at school!

First, a real drop in engine revs, but no change on the rev counter: diagnosis: fuel starvation.

Next, a drop in revs on the rev counter, but no real drop in engine revs: diagnosis faulty alternator.

Then, with the tiller pilot, it was a complete loss of voltage, due to a blown fuse… and there was me thinking our shakedown voyage would be straightforward.

This, I was learning, is what being a practical boat owner is all about.

Enjoyed reading Marine alternator troubleshooting?

A subscription to Practical Boat Owner magazine costs around 40% less than the cover price.

Print and digital editions are available through Magazines Direct – where you can also find the latest deals.

PBO is packed with information to help you get the most from boat ownership – whether sail or power.

-

-

-

- Take your DIY skills to the next level with trusted advice on boat maintenance and repairs

- Impartial in-depth gear reviews

- Practical cruising tips for making the most of your time afloat

-

-