Maximus’s electrics are condemned, so we’ll need to carry out a total boat rewire and the running rigging will need to be replaced... but it’s not all bad news

Our marine surveyor Ben Sutcliffe-Davies switched on the instruments of our Maxi 84, Maximus, and I held my breath. Nothing. We hadn’t expected there to be any life in the batteries after two years on the hard-standing, but it was worth a go. Ben tested the batteries with his multimeter.

“Less than two in that one and we’ve got eight in this one,” he said, “which is why we can’t get anything to work…” When we took on the Maxi 84, donated by PBO reader Daniel Kirtley, I knew we’d have a few jobs to get on with.

Already we’d scraped back the hull to gelcoat, plugged leaks and polished topsides. Now new boat batteries were at the top of the list. What we hadn’t bargained for (and certainly not budgeted for) was a whole boat rewire!

No life in the old batteries

The first challenge was actually finding an electrician. Covid restrictions had just eased, and it meant every boat owner on the South Coast was busy trying to launch. Electricians were in high demand. After a morning on the phone, I got hold of Adam McMenemy of ACM Marine, who was based in nearby Emsworth.

“I can’t start work right away,” he warned me, “but I can spare two hours to come and take a look.” He promised to bring a battery and see if he could get things running.

Article continues below…

Back to Dell Quay

“I’m going to miss Dell Quay,” said my husband James as we turned off the narrow country lane into Dell Quay boatyard in Chichester.

We’d grown to love Maximus’s rural retreat. There was always someone to chat to – Andy in the office, or Jonathan driving the crane. It was a hive of activity – banging metal and power tools, the smell of varnish, paint and summer berries.

We were beginning to recognise new boats and miss the ones that had gone. Contrary to first impressions, Dell Quay was a busy, thriving yard, where boats were not decrepit but progressing… albeit some more slowly than others.

Dell Quay is a homely, traditional boat yard

Stepping over flaked anchor chains, I’d peer down the insides of horizontal masts, feel tufts of matted string poking out from clinker hulls. If ever you wanted to know what boats were made of, this was the classroom; every hull type, keel shape, rudder, prop and anode was on display.

I popped in to see John, the welder. He explained the difference between forging and welding and showed me the marshmallow fire irons he’d just started. Last week it was a metal giraffe… I wondered if he ever got round to ‘run-of-the-mill’ boat stuff.

But it was the dogs who gave us the best welcome of all – usually snuffling around the car for food and keeping us company on long, laborious days of DIY. “Yes, I’m definitely going to miss Dell Quay,” I told James, watching a goldfinch flit about the hedgerow. “I’m not sure I’m going to want to leave.”

Adam inspects the old electrics

All I can say is, be careful what you wish for. Within five minutes of arriving at the boat the electrician condemned the electrics… we weren’t going anywhere soon.

Starting in the cockpit, Adam lifted the cables leading from the GPS antenna.

“You can see where this is cracked,” he said. “The UV has just broken down the plastic. The next stage is that water will get inside.” Adam explained that the wiring should have been run through a conduit, and that way, if the conduit breaks down it can easily be replaced before any of the wiring is damaged.

Pretty much every cable Adam touched was stiff and brittle. At the mast, he found the loose, severed ends of the wind indicator cable, and he puzzled over a black box.

The old electrics on Maximus

“I don’t know what that’s for, but whatever it is, the wiring’s been squashed,” he said. “It could be there’s a connection inside there, but it should be going through the deck, not to a junction box. It’s not even properly waterproof.”

Adam suggested the cables should be fed through a Scanstrut deck seal. He lifted the loose, corroded deck plugs, and held the cable between his fingers. “These cables are rock solid and split,” he pointed out. “If they’re like that down here, then it’s going to be worse at the top of the mast.”

The mast was going to have to come down for a full rewire, but at least it would be a good opportunity to replace the nav lights with more modern LED equivalents.

Down below, the wiring was no better. A companionway leak had corroded the cabling and instrument panel, and there were patches of household wiring held together by putty and tape.

When I asked if maybe Adam could just pop his battery in and test the systems anyway, he looked at me with disbelief. “It’s too dangerous,” he said. “I’m not putting my battery anywhere near this!”

Oh, OK. I guess there was no getting around it, the mast was coming down, and Maximus would be staying in Dell Quay after all. On the plus side, if the mast had to come down then at least we could get the rigging inspected at the same time.

Barry Locke the rigger kindly stepped onboard and checked the rigging

Rigging check

It was at this moment that Adam demonstrated some remarkable psychic powers. “You should speak to Barry the rigger,” he said. Not a minute later, a red car pulled up outside Maximus and Barry himself got out.

There was me, spending hours on the phone trying to summon a single tradesperson in high-season, and Adam managed it with a simple sentence. “Hey Barry, come and check out the rigging,” he called.

Barry, who coincidentally was at the yard to inspect the boat next door, kindly stepped on board to take a look.

The good news, at least, was that the standing rigging was in fine fettle: good quality Staylock rigging screws, a Sailspar furling system that worked fine, a sliding gooseneck on the boom and a perfectly set-up mast with a bit of pre-bend.

Adam pointed out what looked like rust at the bottle screws, but Barry reassured us it was dirt.

“You’ll get that because what happens is that there’s wire inside the wire, and if the inside is a bit dirty, the water runs down the wire and that’s the only place it can sit,” he explained.

The running rigging, on the other hand, had had its day. “What if we just give it a good clean?” suggested my husband James, reading my thoughts. After all, it had come up remarkably well when we’d used the pressure washer.

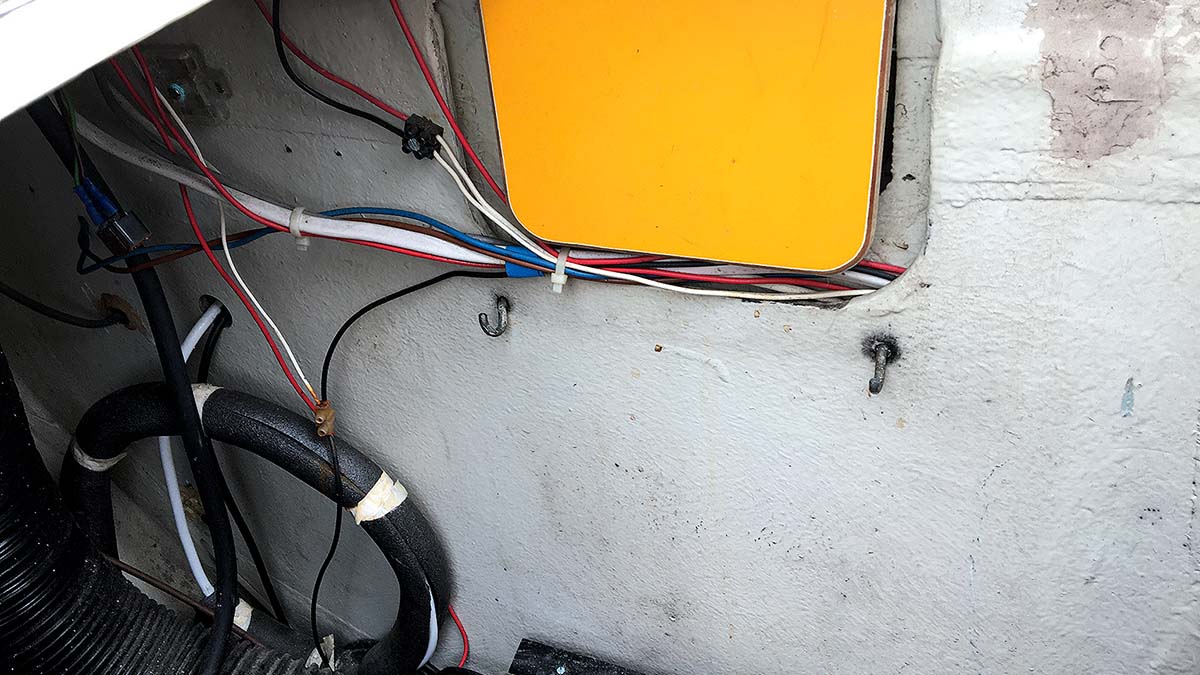

The old cables fed through a funny serving-hatch kind of arrangement from the cockpit locker into the boat

Barry shook his head. “The outer cover of the rope is rotten. When you try and wash it the inner core will come out of its cover. It’s not worth it.”

Barry explained that when we replace running rigging we need to tie a mousing line on the end of the ropes, pull them out, and leave the mouse lines in place so the new ropes can easily be replaced.

“Whenever I make halyards I’ll splice a loop in the end for the mouse line,” he added. “That way, in the winter you can take them out and they’re not going to be destroyed by the bad weather.”

The wiring should have been run through the mast conduit, but was instead routed down the centre inside this foam tubing

Barry wasn’t a fan of the white plastic tubing over the baby stays, which was there to protect the jib sheets when you tack. “Personally, I’d do away with these,” he said. “I don’t like them because they get so mucky. You need to lift them and clean them on a regular basis – let the air get to the rigging.”

Barry agreed to come back when the mast was down for rewiring and check the sheaves and replace the running rigging.

Mast comes down

I returned to the boatyard a week later. I was pleased to see that Jonathan had plugged the hole where the old heating vent had been. I also had a new neighbour, a smart Westerly Centaur, which looked tiny from Maximus’s deck, resting on its bilge keels.

It was so hot that day the cheese in my sandwiches melted, and a steady flow of kayakers and paddleboarders dragged their kit through the boatyard to the slipway. I looked on enviously as holidaymakers – and even fellow boat owners – downed tools and went wild swimming.

Adam pulls out the old wiring

Even the local seadogs, Stanley, Jennifer and Jazz, had abandoned me, preferring to splash in the harbour among the houseboats. Next time, I vowed to bring my swimsuit.

Still, back to work. It was strange to see Maximus without her mast, but nice to meet Greg Wells from Raymarine, who popped by to deliver our new VHF and other kit. We had a good chat about the Sailor radio and where to place the new electronics.

Meanwhile, Adam and his colleague Ciaran were busy working on the mast, which was now on trestles on the opposite side of the boatyard. Instead of being routed through a groove inside the mast, the original cables for the tri-light, aerial and wind indicator had been run down the centre of the mast.

Wiring for the old masthead light was looking rather the worse for wear

“The worst thing is all the burns in the foam,” said Adam. “They put the foam there to stop it slapping on the mast and making a noise, but what they should have done is put the wiring through the conduit inside the mast.”

It was also a single household wire in the mast, clearly not the original wiring. Adam showed us the tricolour light at the top of the mast, which was crazed and UV damaged. He pointed out the domestic cable, and how it differed from proper marine cable.

“Really, the wire should be two- or three-core in a jacket which will give it extra protection,” he said. Pointing at the marine cable he added: “Here you have two wires on the inside and then an inner core and an outer core.”

Proper marine wiring is much more flexible than domestic household wiring

Adam normally buys marine-grade cable in 100m reels. It’s a tin-coated copper wire which, he points out, is more resistant to corrosion over time.

He demonstrated how easy it is to snap domestic wires between your fingers; it took a lot more effort with marine wire. Marine wiring has thinner strands which are more flexible and harder to break.

The plastic, or ‘jacket’ around them is also a lot bendier, which is important as boats are moving and flexing all the time. Once Adam and Ciaran had removed all the old cabling from the mast, along with the light fittings and the old wind unit, they cleaned the mast, its base and masthead.

Adam and Ciaran get to work. Ciaran is holding the worn foam tubing which had been installed to stop the wiring flapping

Running in the new wiring

They then got all the cables together for the new instruments and held them through their fingers while they fed them down through the mast channel.

“It’s important we put all three (tricolour, aerial and wind indicator) in one go,” explained Adam. “It’s a tight space and we need to get them straight. If they twist we have to start again.” Lubricating the wires helps them run smoothly when being pulled through the mast conduit.

VHF aerial

Always replace the VHF aerial, as it’s a safety feature, Adam advised, but if you’re going to the cost of taking your mast up and down (around £100 each time), you might as well replace the other items, which get sun-damaged and wind-beaten over time.

Adam recommended we get the Shakespeare Vtronix stainless steel whip antenna and Hawk wind indicator, which comes as one unit and is lightweight and low-windage. At the same time, I ordered an inflatable emergency antenna from Shakespeare Marine, for use if the main VHF antenna fails.

Yachting journalist James Turner had demonstrated one when he visited Maximus, and I was impressed by how quickly it inflated to 5ft using a CO2 cartridge in the same way an automatic lifejacket does (but you can also manually inflate it).

A small hitch with the Vtronix aerial was that it didn’t fit the old bracket. Not to worry, we knew someone who could fix that! Welder John Gillespie very kindly put aside his latest artistic creation and made us a bracket for just £20.

The smart new Osculati tri light for the top of the mast

Navigation lights

The two lights we needed to fix to the mast were the tri-light and steaming light. On Adam’s recommendation we sourced these from Osculati. In particular, he’d been impressed with the Navigation and deck LED light (a 225° white light for motoring at night).

Osculati, an Italian company, was also about to launch its LED tricolour light to the UK market, so we decided to try this too. As well as having the regular white, red and green lights for sailing at night, it functions as a 360° mooring/anchor light.

Note: We may earn a commission when you buy through links on our site, at no extra cost to you. This doesn’t affect our editorial independence.

Which nav lights are permissible where?

I found this diagram (right) from the Osculati website extremely helpful when trying to remember which navigation lights we needed to comply with the International Regulations for Preventing Collisions at Sea (Colregs).

Maximus is a sailing boat under 20m so can have a single green/red and white stern light – also known as a tri-light – installed on the masthead.

However, when motoring at night the steaming light needs to be HIGHER than the navigation lights, so the tri-light won’t do.

Instead, we needed to install side lights on the pulpit and a steaming light mounted higher up (we chose to put this halfway up the mast).

As the mast steaming light only shines forward, we’ll also needed a stern light to show at the transom.

Ali found some Mclube onboard and cleaned and lubricated the sheaves at the top of the mast

Stiff sheaves

The sheaves at the top of the mast, where the halyards pass through, were stiff and difficult to turn. Adam took the pin out, gave it a good clean and lubricated it with Vaseline to allow it to turn enough to get the wiring through.

Ideally Barry the rigger would have checked over the mast before the rewire, but he was on holiday at the time and we didn’t want to lose our slot for electrics.

It was approaching the end of summer, and after a year of lockdowns, we were desperate to launch Maximus so we could have some kind of holiday with the kids. Chichester Marina was beckoning!

The inside of a mast – not something you see very often (nor want to!)

With just a week to go until the next spring tide (the only time we could launch) we realised we wouldn’t have time to replace the running rigging as we’d hoped, but we didn’t want the mast to go back up without being checked.

Fortunately, Luke at Holman Rigging, based in Chichester, came to the rescue, and despite being very busy managed to squeeze us in. He gave us a quote outlining what needed to be done while the mast was down, and what could wait until later when we were at Chichester Marina.

Luke removed the mast base sheaves and gave them a good clean and re-installed the heel. He then replaced three rivets on the radar reflector and properly fixed the lazyjack fittings. Sadly the rest of the jobs, and especially the new running rigging, would have to wait for now.

The sheaves get a clean

While the engine, deck and cabin wiring would have to be completed later, Adam did come up with a solution to get us safely to the marina, 20 minutes downriver. He lent us a starter battery and did a temporary wiring fix so that the engine would start. We were (almost) safe to enter the water!

I called PBO’s engine expert Stu Davies, who kindly promised to come down the following week with his wife, Laura, to take a look at the MD2020 Volvo Penta engine. Finally it looked like things were falling into place!

Thanks to our Project Boat Supporters

Dell Quay Marine, Osculati, Raymarine, Shakespeare Marine, TruDesign, Screwfix, Coleman Marine Insurance, MDL Marinas, Premier Marinas, seajet, Marine & Industrial, Clean to Gleam, Dometic, West System, Farécla, Navigators Marine, Lewmar, RYA, Aqua Marine, Ecobat, Victron Energy, Scanstrut, T Sails and XP Rigging.

Why not subscribe today?

This feature appeared in the February 2022 edition of Practical Boat Owner. For more articles like this, including DIY, money-saving advice, great boat projects, expert tips and ways to improve your boat’s performance, take out a magazine subscription to Britain’s best-selling boating magazine.

Subscribe, or make a gift for someone else, and you’ll always save at least 30% compared to newsstand prices.

See the latest PBO subscription deals on magazinesdirect.com