Emrhys Barrell tests a dozen 12V lithium boat batteries (60-120Ah) with integral charge monitoring and the results are surprising

Boat owners have long relied upon the lead-acid battery to start their engines, run electric lights and, these days, to power inverters to run household items such as kettles, microwaves and more. Yet lithium boat batteries offer much better performance and lifespan, but at a much higher up-front price. So is it time for you to switch from the 19th century technology to the 21st?

The generally accepted rule of thumb with lead-acid is that your battery pack capacity should be double what you are likely to use in one day, or between recharges. This is because most lead-acid batteries should not be regularly discharged to below 50% of their capacity, or their cycle life will rapidly diminish. Some lead-acid technologies will improve on this, but at greater cost.

At the same time the faster you take power out of a lead-acid battery, the less overall capacity you will get. Typically a battery that will give you 100Ah if it is discharged at 5A, ie over a 20-hour period, will only give you 80Ah if you discharge at 20A, ie over 5 hours, and 50Ah if you discharge at 100A, ie over a nominal 1 hour.

This becomes especially significant if you are powering an inverter, or driving an electric boat. Thus your nominal lead-acid battery capacity will have to be even greater if you are regularly taking out high currents.

In addition, the number of useful cycles any battery will give you over its lifespan is governed by how low you take its charge each time, known as Depth of Discharge (DoD), and how fast you take the power out.

The cheapest lead-acid leisure battery on sale in your chandlery will probably give you at best 100-125 cycles at 50% DoD. Regularly take this down to 80% DoD and the figure will drop to 25-30 cycles, at which point you will probably only have 50-60% of the original maximum capacity remaining. If you take the capacity down to 90% DoD – when the lights start to dim – you will probably get 10-20 cycles at most.

Note: We may earn a commission when you buy through links on our site, at no extra cost to you. This doesn’t affect our editorial independence.

Better leisure batteries on sale will improve on these figures, but usually not by much, and you’ll generally have to look to traction batteries, designed to power electric vehicles, to get over 500 cycles at 80% DoD. Deep Cycle batteries from Vetus, and Lead Carbon batteries from DBS Leoch both claim even greater cycle lives.

And the final bugbear with a lead-acid battery on your boat is sulphation. Leave it over winter at 80% charge, and that will become its maximum capacity, no matter how much you charge it up afterwards.

Do that two years running and you are down to 60%.

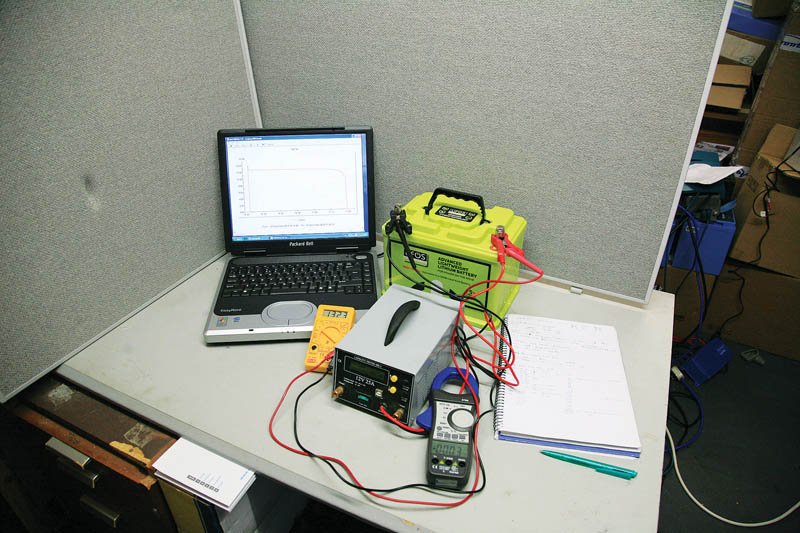

How we tested the best lithium boat batteries

Lithium boat batteries claim to turn all these performance expectations on their head. They claim discharge capacities of nearly 100% even at 100A discharge, and cycle lives of 2000+ at similar discharge currents and 80% DoD.

The aim of our exercise was to put these claims to the test.

To ensure fairness across the range we charged each battery on test with an approved lithium charger – either the one supplied with it, or with a Victron Smart Charger, or Mastervolt ChargeMaster Plus. We then carried out three measured discharges (with recharging in between each) and measured the Ah they delivered:

1. At 25A – using an MK constant current discharge tester

2. At 100A – by connecting each to an inverter, with a 1kW electric heater plugged in

3. At 150A – as above but with a 1.5kW heater

4. Finally we measured the maximum current they would deliver for 5 minutes, on the grounds that this is what you would use to boil a kettle or power a microwave.

- Some batteries being tested only had a 90Ah or 60Ah rated capacity, so we only took 90A and 60A from these to test actual performance compared to claimed performance.

- Some batteries could deliver the 150A, some could not. In all cases it was the internal battery management system (BMS) that determined when they shut down, with different manufacturers choosing different cut-off points that they thought would enable their unit to deliver the best long-term results and cycle life.

- The temperature of our test facility varied between 10-15°C. Most makers’ stated capacities were achieved at 25°C, so our results were bound to be slightly lower than the claimed figures, by approximately 2-4Ah.

Lithium boat batteries for engine starting

None of the lithium boat batteries we tested claim to be suitable for engine starting. For this you need a very high current for short bursts – in the order of 200-400A, and they are just not designed to produce this regularly.

Lithium battery warranties

The warranty figures quoted for lithium boat batteries should be treated with caution. Most are based on figures provided by the makers of the cells, and these can often be hedged with caveats, such as tapering replacement values, rather than full replacement, and stipulations about how the battery has been charged and discharged, which could be difficult to prove if you have a claim.

For this reason you should read the small print carefully, and not assume that a unit with twice the warranty period is necessarily twice as good.

Lithium battery lifecycle claims

We could not verify the cycle life claims of the batteries we tested, but they are all between 2,500-5,000 at 80% DoD (depth of discharge), so are unlikely to all be wrong.

Having said that, when we asked the suppliers how they arrived at these cycle life claims, most admitted that the actual battery had not been cycled 5,000 times by them – it would take around 10 years to carry this out – but were based on figures quoted by the manufacturers of the individual cells inside the batteries.

And hereby comes one of the possible issues with lithium boat batteries. Nearly all lithium cell production is taking place in the Far East, and production standards and safety standards in their manufacture are difficult to verify. While there is an international standard for Transportation (UN38.3), as far as we can find there are few – if any –internationally agreed standards for battery production.

This is an issue that is concerning the UK Government Office for Product Safety and Standards. PBO spoke to them during our test, and they confirmed they are looking into the question of all batteries, including lead-acid, but in particular lithium, with regards to safety in use, and claimed performance, and safety when being transported.

They are looking at composition, capacity, labelling and chemistry, and their first report is due out soon. We will keep you updated on their conclusions, but you can check for yourself at: gov.uk/guidance/batteries

This is not to say that the batteries we have tested are unsafe, but we would suggest that you ask the supplier of any battery you are thinking of buying to supply you with any relevant test reports supporting compliance and safety.

Best lithium boat batteries tested

Sterling AMPS 60 & and AMPS 100

- RRP: £599 (AMPS 60) and £1,250 (AMPS 100)

- Contact: sterling-power.com

Sterling have been supplying battery chargers and inverters for many years and one of their largest markets is emergency vehicles, who use their inverters to power the increasing array of 240V equipment used today. Concerned about the poor performance of lead acid batteries when used at high currents and down to low DoD, they looked for alternatives. Along with the lithium AMPS range they also supply battery-to-battery chargers, enabling the vehicle’s alternator to rapidly re-charge the batteries.

The two units performed remarkably well in the 100A/60A discharge test, delivering 119Ah and 77Ah respectively, both 20% above their rated capacities. The 60 maintained this performance at 95A, but the 100 fell away at 150A, only delivering 55Ah. Sterling put this down to the BMS in the 100 cutting off early. The maximum current figures reflected the same fact, with the 60 delivering 120A for five minutes, but the 100 only delivering 160A. Internally they have four prismatic cells each; outside there’s a removable carry strap.

Super B Epsilon 90

- RRP: £1,860

- Contact: super-b.com

The Super B was the most expensive unit on test, but also one of the best performers. Its nominal capacity is only 90Ah, but it maintained this at 25A, 100A and 150A discharge. It also delivered 190A for five minutes. This will be down to the fact that it has a multi-cylinder cell arrangement internally.

The Super B was the most expensive unit on test, but also one of the best performers. Its nominal capacity is only 90Ah, but it maintained this at 25A, 100A and 150A discharge. It also delivered 190A for five minutes. This will be down to the fact that it has a multi-cylinder cell arrangement internally.

Externally it has two carrying handles that fold flush, and labels with its full specification, and safety precautions. When it arrived the voltage was cut back for transport, but you were supplied with an Allen key to open up a plastic panel that revealed a row of dip-switches that you pressed to re-set it for normal use.

A USB memory stick had the full owners manual on it, and an app allows you to monitor the battery from your phone via Bluetooth. Disconcertingly there is no colour-coding for the battery terminals, and you have to peer closely at the symbols embossed in the black plastic case.

The company is based in Holland, and does its own in-house testing for capacity and discharge, with external testing for compliance. The cells come from China.

Mastervolt MLI-E

- RRP: £1,530

- mastervolt.com

- Buy now from Aquafax.co.uk

Mastervolt is one of the largest companies on the world marine electric power market, with a wide range of chargers, inverters, and batteries. They have had large 24V lithium boat battery packs for some years now, fitted to many of the biggest sailing yachts and superyachts, but this is their first self-contained 12V unit. In fact, apart from different colours for the plastic handles, it looks very similar to the Super B Epsilon 90 (above).

Mastervolt is one of the largest companies on the world marine electric power market, with a wide range of chargers, inverters, and batteries. They have had large 24V lithium boat battery packs for some years now, fitted to many of the biggest sailing yachts and superyachts, but this is their first self-contained 12V unit. In fact, apart from different colours for the plastic handles, it looks very similar to the Super B Epsilon 90 (above).

Certainly the performance figures are almost identical, and all the same comments about the case and the BMS apply, including the lack of colour coding for the terminals. Mastervolt say the battery has 240 cylindrical cells in it, and it is built, assembled and tested in the Netherlands.

Both this and the Super B have an identical LED display on the top showing state of charge, and warning you of low voltage, and they both offer you an App to monitor the battery via Bluetooth.

Transporter

- RRP: £1,195

- Contact: transporterenergy.co.uk

Transporter is the European division of the US company Dragonfly Energy, which is big in the recreational vehicle (RV) market. All its products are assembled and tested in the USA.

Transporter is the European division of the US company Dragonfly Energy, which is big in the recreational vehicle (RV) market. All its products are assembled and tested in the USA.

The one Transporter unit presently available has a multi-cylinder internal make up, using the ubiquitous 18650 cells. Externally it differs from all the others on test in having copper lugs with nuts and bolts for connecting the positive and negative cables, as opposed to recessed thread stainless steel terminals. Transporter say this gives a better electrical connection and avoids straining the internal connection to the cells if you should overtighten the bolts, or if they should corrode after some years service in a salt-water environment.

It has a removable carrying strap. It performed well up to 100A, but if the current exceeded this, even by 1A, after 30 seconds the BMS shut-down, and would not reset until you applied a charge voltage. This is clearly a design decision intended to prevent damage to the battery in the event of repeated long-term overload, but it seems unnecessarily fierce to us.

Victron Smart 100

- RRP: £1,465

- Contact: victronenergy.com

- Buy now from eBay

Victron are another major player in the world portable power market, including marine, off-grid, and back-up power supplies, with chargers, inverters, solar panel controllers and a wide range of batteries.

Victron are another major player in the world portable power market, including marine, off-grid, and back-up power supplies, with chargers, inverters, solar panel controllers and a wide range of batteries.

Up until now their lithium boat batteries have required a separate external BMS, and the Smart 100 is the same, but we are told new self-contained units are coming out shortly. Internally the cells are of the four large prismatic type, with active continuous balancing. The batteries are assembled in China or Eastern Europe, but the company carries out its own in-house testing.

Externally the unit suffered from no colour coding of the terminals, with just embossed symbols, and had no way of lifting it except a tiny ridge round the top of the box.

Performance was excellent, exceeding its rating at 25A, 100A, and 150A, and delivering 205A for five minutes, and it has a phone App for battery monitoring.

Relion RB100 and RB100HP

- RRP: £1,000 (RB 100) and £1,100 (RB100HP)

- Contact: dbsleoch.co.uk

- Buy now from eBay

Relion are another US company, with an extensive range of lithium boat batteries, 12V, 24V and 48V, all made in China, and new models coming out all the time. They work in all the off-grid markets, and have their own development division.

Relion are another US company, with an extensive range of lithium boat batteries, 12V, 24V and 48V, all made in China, and new models coming out all the time. They work in all the off-grid markets, and have their own development division.

The two units we had for test vary only in their maximum current capabilities, and as we understand it are similar internally, with multi-cylinder construction, but different BMS settings. This was borne out in our tests, with both delivering close to their rated capacities at 25A and 100A, but the RB100 giving just 82Ah at 150A, compared to the RB100HP’s 102Ah.

Maximum currents showed the same difference, with 178A for the RB100 and 198A for the high power version.

The RB100 has a pair of folding plastic lifting handles, as opposed to the RB100HP which has a lifting strap.

3 Lion 3L-100

- RRP: £1,299

- Contact: roadpro.co.uk

The 3 Lion is supplied by NDS from Italy, one of the largest European players in the off-grid market, with an extensive range of chargers, inverters, solar panels, controllers, and lithium boat batteries, catering for the RV and caravan market as well as for boats.

The 3 Lion is supplied by NDS from Italy, one of the largest European players in the off-grid market, with an extensive range of chargers, inverters, solar panels, controllers, and lithium boat batteries, catering for the RV and caravan market as well as for boats.

Because of this the battery comes complete with a multi-function control box, and display, which takes power from each source – engine alternator, solar panels and charger – balancing the need of the battery, and then distributes it to various outlets, with all functions being shown on an LCD display. This is all included in its price.

Externally the case was similar to several others in the test, suggesting many of them may well come from the same Chinese factory. Positive and negative terminals are colour coded. Internally it has 132 cylindrical cells.

Performance was above its rated figure at 25A, close at 100A, but only 82Ah at 150A. Maximum current was 190A for five minutes.

EZA 100 and EZA 130

- RRP: £1,299 (EZA 100) and £2,995 (EZA 130)

- Contact: roadpro.co.uk or eza.fr

- Buy now from eBay

French company EZA is another major player in the off-grid, RV market. The 100 has prismatic Chinese cells, but they are assembled in Europe, and have a sturdy metal case compared to the plastic of all the others. The terminals are close together, and you would need to be careful with your spanner when connecting them. The unit has an internal BMS, and an array of LEDs on the top indicating state of charge.

Performance is close to its rated figure at 25A and 100A, but as it does not recommend being discharged at more then 100A we stopped here.

The EZA130 is a very substantial and sophisticated unit, again designed for the RV market, and assembled in France in a metal case. It has two inlet sockets and two outlets, and is designed to be connected to inputs from the engine alternator, plus an array of solar panels and a mains battery charger.

The two outlets will supply normal 12V demands, plus an inverter. Inside it has an integral battery-to-battery charger, designed to be used with the latest vehicle smart alternators, and a solar controller. It has an automatic shut-off that disconnects the battery when not in use for long periods.

Performance was up to its ratings at 25A and 130A, but again this was the maximum it was supposed to be discharged at.

Lifos 68

- RRP: £699

- Contact: solartechnology.co.uk

- Buy Now from eBay

The Lifos is new onto the market, and while it was below our target 100Ah, we included it as it could be of interest to the smallest trailable boat, or as power for a small electric outboard. The company has larger models in the pipeline.

The Lifos is new onto the market, and while it was below our target 100Ah, we included it as it could be of interest to the smallest trailable boat, or as power for a small electric outboard. The company has larger models in the pipeline.

It has a neat folding plastic handle, and its terminals have clever brass tapered posts, which can be used for battery cables with clamp ends, or unscrewed for ring connectors. Internally it has four prismatic cells, and is made in China under licence to Lifos.

Performance was at or close to its rated figures at 25A and 65A, but above 70A it shut down, in line with its specification.

Compare specifications and tested results for Lithium batteries reviewed: 3 Lion 3L-100, EZA 100, EZA 130, Lifos 68, Mastervolt 90, Relion 100, Relion 100HP, Sterling 60, Sterling 100, Super B 90, Transporter 100, Victron 100

Lithium boat battery test conclusion

In simple terms, all the batteries on test delivered within 3-4Ah of their claimed maximum outputs at 25A and 100A, with some even achieving this at 150A.

Also as the lithium battery discharges, its voltage remains nearly constant, only falling away during the last 10% of the time. In contrast a lead-acid battery voltage falls in nearly a straight line, so the actual power available in a lithium battery is greater.

However, even though prices are falling, the headline figure for lithium boat batteries still looks daunting at more than five times the price of seemingly equivalent lead-acids.

But if you get ten times the number of cycles, then the whole-life cost becomes half. And of course there is the reduction in weight. Straight from the box, a lithium battery is around half the weight of lead, but factor in the increased capacity and the weight saving becomes even greater.

- Buy the Sterling AMPS 60 now on Amazon

- Buy the Super B Epsilon 90 now on eBay

- Buy the Mastervolt MLI-E now on Aquafax

Which is the best lithium battery for my boat?

We normally try to give a suggested best buy in our tests, but in this case there is no one clear winner, and no single test measurement that we could fairly apply.

For instance the Sterlings give you more Ah for your money, but the Victron, Super B Epsilon, Mastervolt and Relion 100HP give you higher continuous currents.

All the units deliver almost exactly their rated Ah, within our experimental tolerances, but the claimed cycle lives vary. None of these cycle life figures could be verified in our test, and may have been estimated using different depth of discharges. But in any case all reckon to give you at least 2,000 cycles, which for most leisure users is probably at least 20 years of normal use.

Similarly the prices could vary as soon as retailers start discounting them, and again prices are all moving rapidly – usually downwards – as the market expands.

It is generally agreed that those with multi-cell construction will have longer ultimate lives, but at a higher price, and again this is relative and unlikely to be significant for private use, but could become more important for something like a daily use ferry for instance.

Are lithium boat batteries worth the money?

So is lithium for you? Well, being realistic, if you only use your boat 10-20 times a year, and just run lights and navigation equipment, then lead-acid still probably wins by being more cost effective.

But buy the best you can find, with a gel-type top of the list. Keep it well charged up and with sensible use it will last ten years.

But once you start going out more often, or running an inverter, then lithium boat batteries become worth looking at. And bear in mind that new lithium models are arriving, and prices are falling almost by the day.

Why not subscribe today?

For more articles like this, including DIY, money-saving advice, great boat projects, expert tips and ways to improve your boat’s performance, take out a magazine subscription to Britain’s best-selling boating magazine.

Subscribe, or make a gift for someone else, and you’ll always save at least 30% compared to newsstand prices.

See the latest PBO subscription deals on magazinesdirect.com