Simon Westmacott explains how he addresses different contaminated fuel problems to keep his engine running clean and free of diesel bug.

Got contaminated fuel problems?

Much has been written about the issue, particularly the advice from Marine 16’s Peter Weide piece in the PBO November 2023 issue and Nick Houlding’s piece on combining different diesel bug treatments from last spring. Diesel bug seems to be getting more common.

Before you can start troubleshooting your fuel system, you might want to make sure you understand how it works, and have a think about how you’re using your particular engine. The boat I sail, a 2002 Bavaria 36, very definitely needs to use its engine and after some previous fuel issues a dozen years ago, I now minimise risk.

Since marine diesel doesn’t come pre-treated, here are some fixes you can try if contaminated fuel problems do arise.

Contaminated fuel problems: my solutions

Of course, it’s always better to prevent diesel bug from the outset, but here’s what to do when you can’t.

For those lacking budget, space or both for a purpose-made Diesel Dipper (PBO July 2023), I have a couple of rigs that cost no more than about £60 and now give just about 100% peace of mind.

The penalty is that they do involve a bit of time and are only practicable for relatively small quantities of fuel. I have four 20lt cans which currently is enough for us for a single fill.

PUMPING IN: to avoid contaminated fuel, Simon Westmacott buys fresh diesel from a service station and pumps it into his boat from fuel cans. Photo: Simon Westmacott.

The first rig cost me nothing because I had some 10mm copper tube in the back of my workshop and I always keep assorted sizes of plastic tubing. I also had a generic 5lt oil extraction vacuum pump. The bottle I used is an old 1lt orange juice bottle.

Assuming you have a fuel tank with a hole in the top – typically for the fuel gauge sender – the rig extracts whatever is in the very bottom of the tank.

In the Bavaria, removing the fuel sender unit makes reaching the bottom corner of the tank easy. The rig consists of three pieces of 10mm copper tube, some plastic tube, the orange juice bottle and some sealant. Pumping gently will pull whatever is in the tank out from the bottom – pump too hard and the bottle collapses.

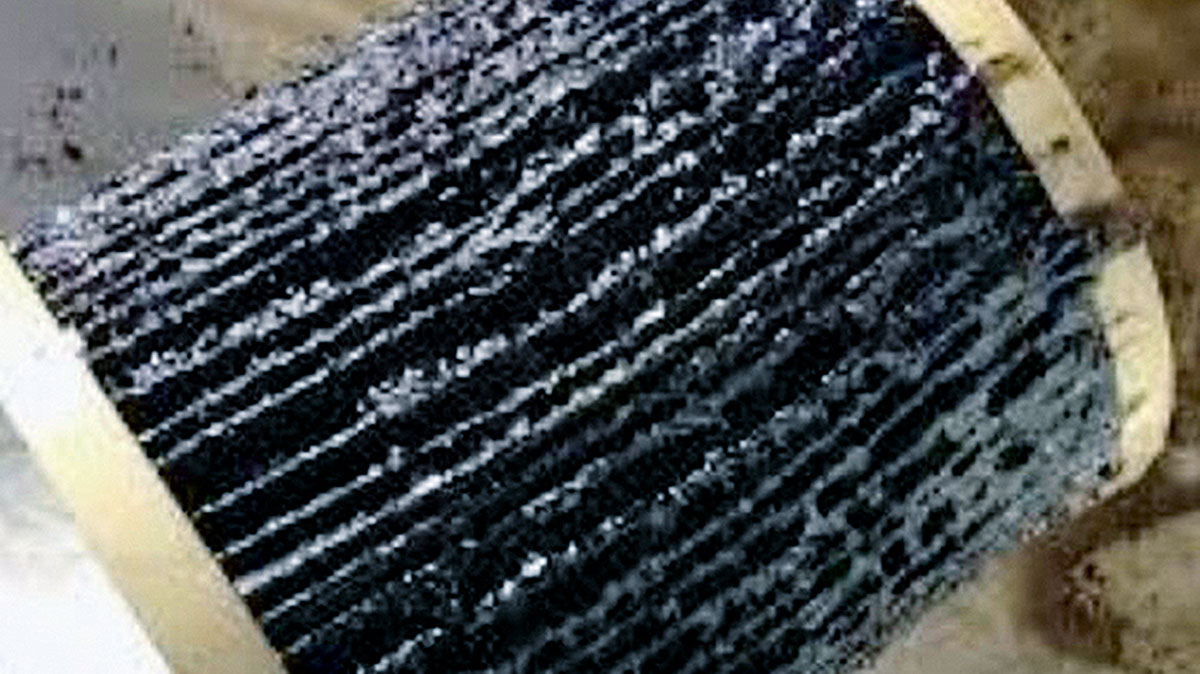

Slowly drawing contaminated fuel through the bottle allows water to settle in the bottom. Photo: Simon Westmacott.

Empty the tank

The purpose of the juice bottle is so you can see clearly, by holding it up to the light, what was in the tank.

Typically, this will be black asphaltenes which are harmless but do clog filters, emulsified water droplets or even neat water, as happens when someone leaves the cap off the fuel filler and it rains.

Empty the bottle and keep pumping as necessary. If in doubt, remove and cap the bottle and leave it to stand for a few days when asphaltenes or water will have fallen to the bottom.

Until recently, I used to do this procedure every spring before launching.

DRAINING OUT: copper pipe is lowered into the fuel tank and fuel is sucked out via the viewing bottle. Photo: Simon Westmacott.

In 2018 Marine 16 changed its advice about brimming tanks at the end of the season given all the problems with biodiesel and speed of fuel deterioration. Our tank holds 150lt and we often don’t use that much in a season, so some of the fuel would have been several years old.

The Volvo Penta MD2030 engine had been smoking unusually on start up so I took the injectors in to Peter Cross at Rochester City Diesel. He dismantled them on the spot with the comment “Whatever have you been running this on? It doesn’t even smell like diesel.”

Asphaltenes

More to the point were the asphaltenes, clearly visible on the bench.

Peter is a fan of BP Ultimate fuel so I agreed the best solution would be to dump the remaining fuel and switch to Ultimate. So I pumped out the 40lt left in the tank (it wasn’t wasted, but burnt instead in the club’s diesel heater).

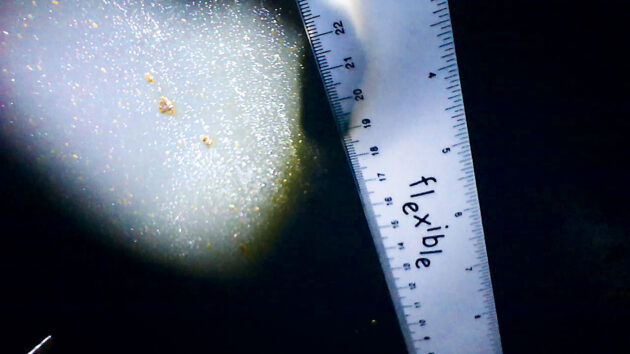

Using a tightly focused head torch, I could see into the tank down to the bottom. The sides were covered with a thin slime with curious blotches.

Light from a head torch reveals slime and other contaminants in the fuel tank. Photo: Simon Westmacott.

Peter Weide then advised a double dose of Marine 16’s Diesel Injector Cleaner, as well as the Diesel Fuel Complete which we were using anyway. Before we launched, I put 60lt of Ultimate in plus the additives. The net result after using most of this mix is that the inside of the tank is pristine.

Through the season I’ve kept enough fuel in the tank for short-term needs, the objective being to keep fuel as fresh as practicable. Either this year or next, I’ll be draining the tank again at the end of the season, using up the fuel in a car.

There is of course the possibility of our tank having crud lodged behind the anti-surge baffles but we have done plenty of rolling and bumping around this year and nothing has arrived in the transparent fuel filter bowl which I added when re-locating the filter.

Transferring fuel

That leads on to my second rig which I use for both pumping out and pumping in.

It’s a Jabsco drill pump and about 6m of ¾in reinforced hose which is very flexible and clings well in the tank filler neck. I found both online at Pump Sales Direct; the pump is rated for diesel use although it does say dismantle and wash with detergent before storage. The copper is standard 22mm plumbing tube.

Pumping in 20lt takes about two minutes; my Ryobi 18V drill still shows full charge after 60lt.

Refuelling this way is arguably less hassle than going to the fuel pontoon where the fuel will be of uncertain age and quality, but perhaps not practical if you get through lots of fuel.

Simon Westmacott raised the fuel filters on his Bavaria’s engine and included a priming bulb to make purging the system easier if there’s a problem. Note empty paint pot to catch diesel when changing a filter. Photo: Simon Westmacott.

System improvements to prevent contaminated fuel problems

The final precaution, which I took several years ago, was to raise the primary fuel filter from almost on the floor of the bilge behind the engine where changing filters was not only a real fiddle but hopelessly messy.

It now has an old paint pot hanging below to catch drained fuel. The filter is now higher than the fuel tank and as hand pumping the engine lift pump never seemed to achieve anything, I put a permanent Delphi priming bulb in the line which works perfectly.

Water in the carburettor bowl will stop an engine.

Steve Langton Chimes in: A quick fix for water in your petrol

I was recently skippering a chartered catamaran in Croatia and the first time the dinghy was launched the outboard stopped within a few minutes and would not re-start.

We called the charter company staff who arrived in a RIB and, having failed to get the motor going, took it back to their base. They soon brought it back with another container of fuel, agreeing with my assessment there was water in the old fuel.

Two days later, now using the ‘new’ fuel and with six young people in the dinghy waiting to get ashore, the outboard again failed to start.

Cleaning the carb bowl

I emptied the carburettor bowl and the motor started immediately. The replacement fuel was also contaminated and the water had reached a level high enough in the bowl to block the jets.

I’ve encountered this problem many times, and the first thing I now do is to drain the carburettor bowl. There’s usually a drain plug at the base of the bowl to achieve this, requiring only a screwdriver, although the Suzuki motor we had in Croatia required a spanner to detach the bowl since no drain plug was fitted.

If you have reason to suspect the fuel is contaminated with water, it can easily be removed by means of an empty 1.5lt clear plastic water bottle. Using a funnel, fill the bottle and leave it to stand for a few minutes. Any water in the fuel will then be seen to have settled at the base of the bottle and careful pouring will separate the fuel out.

For good measure, I also filter the fuel from the bottle using a clean cloth or kitchen paper. This is exactly what I did in Croatia, and we had no further problems.

Email your projects and tips to pbo@futurenet.com including high resolution photos where possible. We pay at least £30 for each one published.

Defeating the Diesel Bug: One Tank, Two Clarke Pumps, an Inspection Hatch and a Lot of Elbow Grease

The Owner of this 35 foot sailboat had been fighting diesel bug for four long years. Four years of blocked…

Can diesel bug fuel treatments work together?

PBO reader Nick Houlding wants to know if different diesel bug fuel treatments can be mixed. Peter Wielde from Marine…

How should I look after my fuel to beat diesel bug?

Ali Wood gets some bug-beating advice from Marine 16’s Peter Weide and learns why modern diesel requires more attention than…

12 diesel bug treatments tested

Diesel bug can clog filters and starve your boat engine of fuel just when you need it most. Can diesel…

Want to read more articles like Contaminated fuel problems: keeping your marine diesel clean?

A subscription to Practical Boat Owner magazine costs around 40% less than the cover price.

Print and digital editions are available through Magazines Direct – where you can also find the latest deals.

PBO is packed with information to help you get the most from boat ownership – whether sail or power.

-

-

-

- Take your DIY skills to the next level with trusted advice on boat maintenance and repairs

- Impartial, in-depth gear reviews

- Practical cruising tips for making the most of your time afloat

-

-

Follow us on Facebook, Instagram, TikTok and Twitter