Uric scale can reduce the diameter of sea-toilet hosepipes by half within five years: Richard Hare tests some solutions

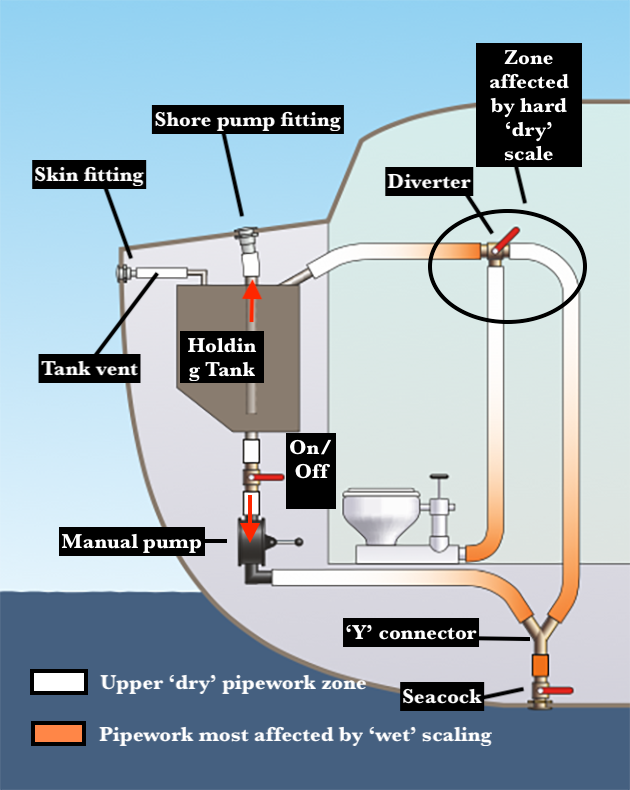

Uric scale accumulates due to the reaction of uric crystals and calcium traces in the water that we pump through, leading us to descale pipes on board. The type of water we use has a bearing here – high-salinity seas like the Med will cause more scale, whereas low-salinity waters like the Baltic and freshwater canals will cause less.

The part of the pipework most affected is below the waterline: it’s here where the lethal cocktail accumulates and is at its richest. Fast-falling ‘dry’ pipework is less affected, but areas where loo waste accumulates for a while – upstream of a diverter valve, for example – can cause higher build-ups of scale, and certainly so if it’s the highly concentrated mix that’s en route to the holding tank.

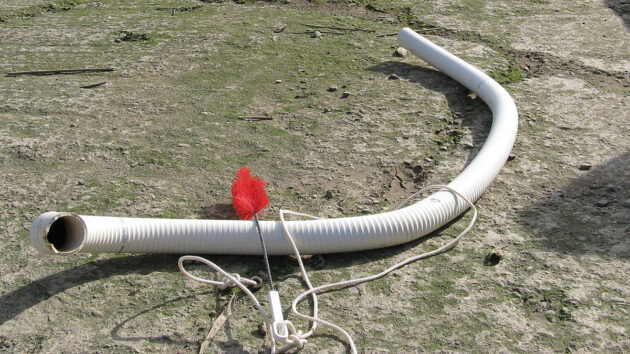

Most lower pipe scale can be loosened by thumping and bottlebrush scrubbing, but a messenger line needs to be dropped down the hose if the brush is to be drawn right through. Credit: Richard Hare

Examination of my Golden Hind 31 Keppel’s 12-year-old pipework suggests there are two types of scale. In the ‘dry’ upper pipework, notably at the diverter valve, the scale was whiter, harder and more bonded onto the plastic than the more friable, softer stuff at the lower, ‘wet’ end of the pipework where the pipe is submerged. Whereas the scale from the lower pipework was shifted easily by thumping and roding (with the hose detached and removed from the boat), the scale around the diverter valve was of sterner stuff. Brutal thumping isn’t an option here.

The hard scale in the upper ‘dry’ pipework was about 1/5 of the thickness of the less dense scale in the lower ‘wet’ pipes, a fact that is likely to be indexed to it being much harder. Keppel’s lower pipework needs cleaning out every five years, but the upper pipework might go for 15 years. We ignore this problem at our peril.

The scale builds up insidiously because we’re unlikely to detect that loo pumping has become stiffer over the years. It’s not until the whole caboodle glugs to an ominous halt that we have to stiffen the sinews and slip on the Marigolds: yes, it’s payback time.

The remedies to descale pipes: thumping and roding

With the pipework dismantled, much scale can be removed by bending the pipe and knocking it around a bit. This dislodges most of the scale, certainly sufficiently for it to be roded out. A good place to do this is where antifouling power-washing is done. Tease out as much scale as possible from each end of the pipe with a bottlebrush and then, by dropping a length of messenger line with a heavy nut attached, the bottlebrush can be drawn through the pipe’s length.

Hard scale in Keppel’s diverter valve. Credit: Richard Hare

However, not all components can be cleaned by bashing them about. Furthermore, we’d ideally want to eradicate the scale without dismantling the pipework. This is where chemicals come in.

Acid solutions to descale pipes under test

Chit-chat on this topic round the club bar usually proffers three solutions – Coca-Cola, vinegar and proprietary descalers – so we put all three to the test. As it’s virtually impossible to get uric scale pipe debris test samples of exactly the same size we took up a suggestion by Ashley Marles of LeeSan that we use seashells; cockleshells in our case. They’re almost solid calcium carbonate – limescale, in other words – and were selected from within a few yards of each other in the River Deben.

Although cockleshells cannot be likened directly with the hard scale we find in our pipes, owing to their hardness they do offer a good test for comparing different lime-scale-dissolving solutions.

We used a reasonable amount of solution, 250ml, to give each test piece a fair chance of being dissolved. The active ingredient – acid – becomes spent as it works, so it would be pointless to experiment with a thimbleful of solution at the bottom of a tiny yoghurt pot.

LeeScale

According to the data sheet, LeeSan’s LeeScale contains phosphoric acid. Although LeeScale can be used neat, the manufacturer recommends that it be diluted at 10-20% with water. We tried it at both ends of the dilution scale.

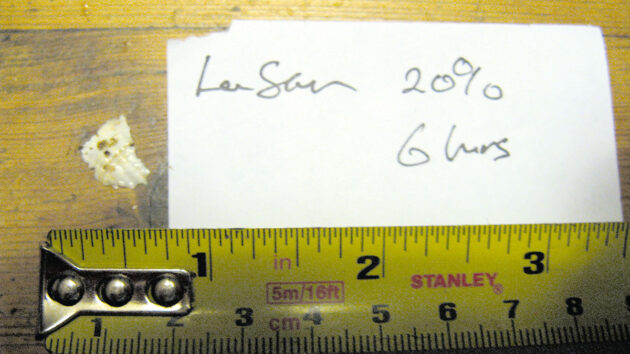

LeeScale 20% after six hours. Credit: Richard Hare

At 20%, the cockleshell effervesced vigorously as soon as it was placed into the solution. Within six hours, it was reduced to a frail shard about 6mm2 , by which time it was effervescing a lot less. It would have dissolved completely at about seven hours.

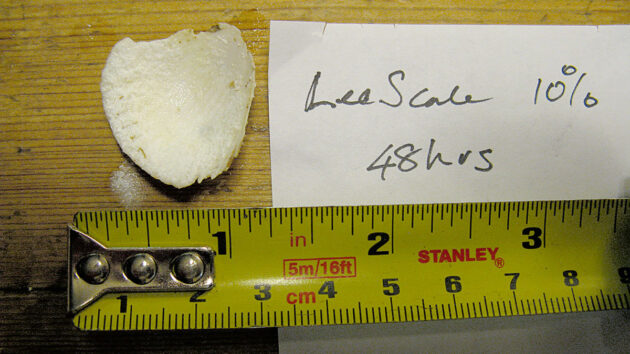

LeeScale 10% after six hours. Credit: Richard Hare

At 10% dilution, progress was slower and less effective. The shell was reduced to about half its volume at 48 hours, at which time the test was stopped as the solution appeared to be exhausted.

- LeeScale retails at about £22 per litre. At 20% dilution with water, 2lt of product produces 10lt of solution at a cost of £44. At 10%, 10lt would cost £22

Distilled vinegar

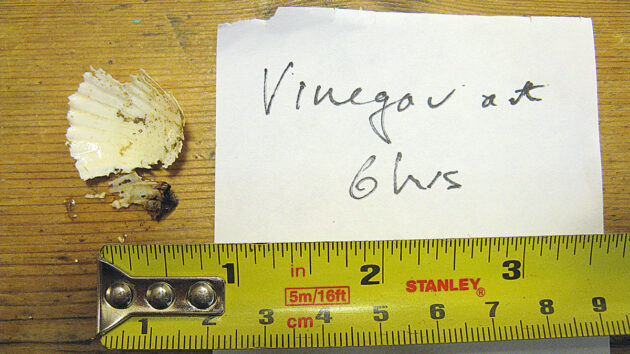

Vinegar after six hours. Credit: Richard Hare

Like malt vinegar, distilled vinegar is 5% acidic so we used it neat. The cockleshell fizzed from the outset but not very briskly at first, becoming more active later. At six hours the shell was reduced to about half its original volume (roughly 18mm2 ), and thereafter progress became markedly slower.

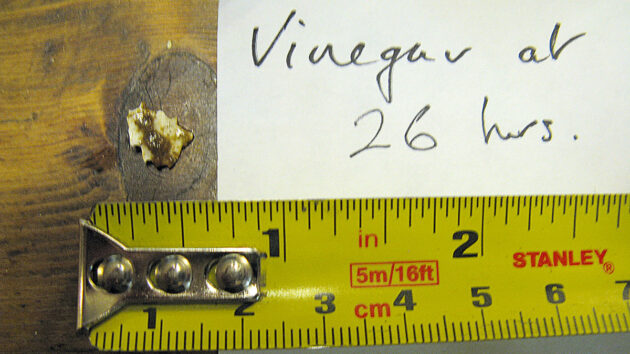

Vinegar after 26 hours. Credit: Richard Hare

At 18 hours it had further reduced to about 6mm2, and at 26 hours it had reduced slightly more. With the solution all but exhausted the shell dissolved to nothing at around 36 hours, while I was asleep. It was gone by morning.

- Distilled vinegar costs around 60p per litre when bought in small domestic bottles, so a 10lt dose costs around £6.

Coca-Cola

Coca-Cola after 48 hours. Credit: Richard Hare

The label tells us that the drink contains phosphoric acid, but doesn’t indicate the proportion. It can’t be much, though. As soon as the shell was immersed it bubbled energetically, but this was shortlived: presumably, the small amount of acid was spent.

The test was stopped at 24 hours as the shell looked pretty much as it did when it first went into the solution.

- 1.25lt of Coca-Cola costs about £1.60 and £2.25, so a 10lt dose costs £12.80-£18.

Acids in practice

After our cockleshell test, we tried all three acidic solutions on hard scale attached to a diverter spigot at the ‘dry’ end of the pipework: this was stuck hard, and attempting to chisel it off would risk damage. Of the three solutions the LeeScale (20% dilution) made the most impression and we were able to prise away almost all of the (still) hard scale. A second dose would probably have made it easier.

However, it would have needed a lot more chemical for it to be soft enough to pump away, while the 10% LeeScale solution, the vinegar and Coca-Cola proved ineffective.

Acidic solutions in ‘wet’ lower pipework

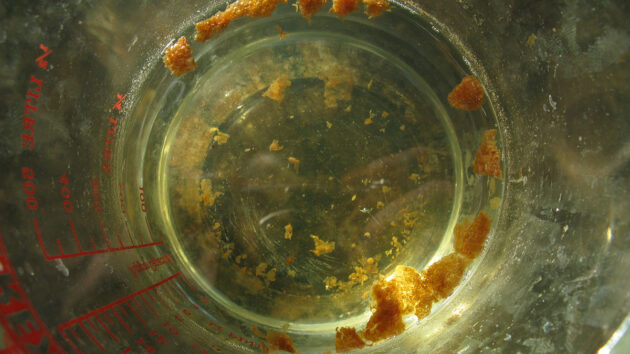

A cockleshell-sized piece of uric scale (above) from the lower pipes was turned into a pumpable slop (below) within 13-20 hours. Credit: Richard Hare

For context, we needed to know how a cockleshell’s performance might equate to that of the softer uric scale found in the lower pipework. To this end we tested an equivalent-sized piece of scale in a 10% LeeScale solution.

Credit: Richard Hare

Where the shell depleted by 50% and went no further, the uric scale reduced to a ‘pumpable’ slop within 13-20 hours, suggesting that soft scale withers quicker than cockleshells or hard scale.

Alkaline solutions under test – ‘dry’ upper pipework

After 24 hours, the LeeScale made little impact. The scale could just be teased away from the plastic with care…Credit: Richard Hare

Unlike the acids, caustic soda (sodium hydroxide) is an aggressive alkaline, commonly used for clearing fatty deposits from drains. It strips paint, attacks aluminium and burns skin, so must be handled with care. It made no impression on the soft scale from the wet end of the pipe, nor upon a cockleshell, but on the stubborn scale on the diverter valve spigot it yielded a surprising result.

This treatment can only be recommended for pipework that is removed from the system. Caustic soda was mixed 100g per litre, and the spigots were soaked for six hours then removed from the solution, which was discarded. At this stage, the scale was still too hard to be removed. The spigots were then allowed to rest on the workbench overnight.

…but with the alkaline caustic soda, after six hours and an overnight ‘rest’, the scale could be cleaned away very easily. Credit: Richard Hare

Come the morning, there was a big difference: the alkaline had worked its magic overnight, and the uric scale was teased away easily with a screwdriver. It came away in clods, like frozen butter. Clearly, the alkaline was attacking something other than scale, but we don’t know what. Fatty traces, perhaps? Uric acid traces?

It’s possible, of course, this outcome results from the combined attack of acid and caustic soda, one after the other.

- Caustic soda retails at supermarkets for about £3 for 500g. At 100g per litre this yields 5lt, so a 10lt dose costs £6.

WARNING Acids and alkalis are harmful even when diluted. Wear protective clothing and never mix the two.

Dosing the system to descale pipes

With our boats out of the water we can trap the liquid in the lower pipework where it’s needed most, and at the right potency. A gravity holding tank is an asset as it’ll be vented, making it a useful vacuum releaser. By first pumping the solution from the bowl to the holding tank and trapping it there, it can then be dropped in a controlled way down to the outlet seacock.

If required, vacuums can be further eased by loosening the joker valve discharge elbow at the back of the pump. Where holding tanks aren’t fitted, breather valves can be used.

With LeeScale – and vinegar, presumably – there is no time limit within which the solution has to be evacuated, so it makes sense to drop a few litres of solution into the pipework as soon as our boats come out of the water. By leaving it locked away in there for a day or two while we’re attending to other matters, it has plenty of time to crack on and do its stuff.

Holding tanks

Holding tanks require special consideration but can also be an aid to dosing. Questionable design: note the downward fall of the pipe from the tank to…Credit: Richard Hare

Holding tanks aren’t affected by uric scale, assuming they’re properly designed and correctly ventilated. According to LeeSan’s Ashley Marles: ‘The scale will not build up as it does in the pipework as the breakdown of waste is far quicker due to the bacteria in the laying waste.’

…the diverter valve, and note the ‘wet’ pipe scale, albeit in the upper part of the system. This is what it looks like after just 15 months’ use. Credit: Richard Hare

Problem Avoidance

Prevention is better than cure, so it pays to reduce exposure to the problem right from the outset.

SCALE TRAPS: Places where waste is allowed to accumulate should be designed out of the system wherever possible, preferably from the outset when the system is first installed.

SHORT PIPE RUNS: The longer the discharge pipe, the more loo pumps will be needed if all the uric acid is to be flushed out of the system, which leads on to…

COPIOUS FLUSHING: ‘Out of sight, out of mind’ is a recipe for trouble when pumping the bowl. We need water that’s free of uric crystals in our pipework if we’re to minimise scale build-up.

MINIMISING ‘WET’ PIPEWORK: By avoiding long submerged runs of soil pipe we will reduce the proportion of pipework that’s most at risk.

PREVENTATIVE TREATMENTS: By dosing annually, the problem may be avoided

Test conclusions

Proprietary products such as LeeScale work effectively, as does vinegar.

Given a healthy dose, a 24-hour soak should work effectively on the ‘wet’ pipe scale, but considerably longer seems necessary for the harder white scale from the ‘dry’ pipework.

- LeeScale at 10% is likely to keep on top of the problem if run through the system once a year. However, if a large accumulation has been allowed to build up over time, the 20% solution is preferable.

- Vinegar can be used as an alternative to a proprietary solution. It appears to be more effective than LeeScale at 10% but inferior to it at 20%. Therefore, it could work as an

annual preventative treatment but would probably not be able to clear large-scale accumulations without the process being repeated several times over several days. - Coca-Cola made no practical impact at all.

- Caustic soda appears to be an effective treatment of dismantled components from ‘dry’ pipework zones, perhaps followed up with an acid solution after careful rinsing.

Sea toilet restoration: How I refurbished the heads on the PBO Project Boat

With seacocks previously installed in the Maxi 84, it was time to connect the hoses. The first thing to decide…

Skin fittings and seacocks explained

Surveyor Nick Vass examines the different types of skin fittings and seacocks on the market and shares advice on how…

Why now is the time to upgrade your marine toilet

Most boats have manual marine toilets on board. This is why you should consider upgrading to an electric unit

Best portable toilet: From compostable to flushable units

We’ve all been there; middle of the night, you need a pee. The marina toilet or camping block is just…

Want to read more practical articles like Solutions to descale pipes on your boat?

A subscription to Practical Boat Owner magazine costs around 40% less than the cover price.

Print and digital editions are available through Magazines Direct – where you can also find the latest deals.

PBO is packed with information to help you get the most from boat ownership – whether sail or power.

-

-

-

- Take your DIY skills to the next level with trusted advice on boat maintenance and repairs

- Impartial, in-depth gear reviews

- Practical cruising tips for making the most of your time afloat

-

-

Follow us on Facebook, Instagram, TikTok and Twitter