The real cost of engineering solutions to a problem that didn’t exist in the first place, muses PBO columnist Dave Selby.

There are three kinds of engineer, and they’re all dangerous, writes Dave Selby.

And that’s because they spend most of their time coming up with solutions for problems that don’t necessarily exist.

One example is the Sinclair C5.

Of course, the washing machine-powered electric trike was relatively harmless, as long as you didn’t use it on the road, but more dangerous are the notions of retired engineers: they have workshops, tools, know-how, benches and vices, they lick pencils (which I suppose is a harmless vice) and live in the Black Country where the national dress is brown store coats. But worryingly, even though they’re landlocked they spend all their time contriving cunning readers’ projects for PBO, for which they get at least £30 a pop, and then have the audacity to claim ‘Project cost: ZERO’, or in extreme cases, ‘£4.99’.

The trouble with this is that if you’re not an engineer you’ll spend more than the £30 on tools alone, and a lot more buying bits which engineers have lying around in their ‘workshop’ – that’s engineering jargon for what we in the south call the house, kitchen, bedroom or bathroom.

They also write in a hieroglyphic language called ‘Brummie’, which Google can’t translate, so that at the end of the day all you end up with is all the individual component parts of a Sinclair C5, washing machine motor included.

But most hazardous of all is the retired engineer with a Sailfish, and there are lots of them. That’s because any engineer who retired in the ’70s or ’80s was presented with a Sailfish 18 rather than the more conventional gold watch, and that explains why the further you get from the sea the more Sailfishes you’ll encounter.

Walsall is a hotspot, and I’m even told that in Dudley they outnumber Reliant Robins.

Retired engineers love the Sailfish because it has the peculiar virtue that whenever you do one job, it creates many more. Engineers relish this.

The only other thing you need to know about engineers is that they think everyone else is an engineer.

I discovered this as soon as word got round Sailfish central in the West Midlands – via home-made fax machines fashioned out of Sinclair C5s – that I was thinking about going sailing.

Soon after that I started getting crackly phone calls: ‘Yow didn’t answer my fax,’ they said, which is engineer talk for ‘hello’.

‘We don’t have faxes in the south,’ I said. They ignored that.

‘So yow’s going sailing, are yow? Here’s wot yow needs to do, lad. First yow’s got to extract yow compression post to make sure it ain’t boogered.’

That was former Rolls-Royce man Bob, who had sown the seed that my wooden compression post, which stops the boat from collapsing into a flat-pack when you tighten the rigging, might be rotten at the bottom if water had got into the foam-filled void under the cabin floor.

I bought hole-cutters – cost: more than £4.99 – and drilled a couple of inspection holes through the cabin floor. Bob was right; the foam was soggy.

As for removing the compression post, former foreman Bob said: ‘Now, yow gives it a whack.’

‘What with?’ I asked. ‘Yow whacker,’ said Bob, incredulous at my lack of engineering nous.

In my local hardware shop they didn’t have a clue either, so I bought a rubber mallet, cost: MORE THAN ZERO.

I whacked the post. Nothing happened.

‘That’s cos yow hasn’t removed yow tabernacle screws,’ said Bob, in a smug sowperior manner.

‘That’s cos yow didn’t tell me to,’ I snapped sarkily.

I removed the tabernacle, gave the post a whack and it came free.

The bottom of the post was wet, but when it dried out I found it was totally solid and rot-free.

‘Now yow impregnates yow post with carbopolytetrahydrochloronitrousradium,’

said Bob.

‘Wos that?’ I asked, knowing the answer wouldn’t help.

‘Yow’ll have all yow ingredients in yow workshop,’ said Bob with an air of careless triumph.

I bought wood preserver, cost: A LOT MORE THAN ZERO. But this whole pointless exercise in solving a problem that didn’t exist has cost me a lot more than that. It has also created at least four other jobs.

I now need to buy foam and squirt it into the inspection holes I made; buy a glassfibre kit and glass over the top; buy dowels to glue into the tabernacle screw holes which had become enlarged over time; buy sealant to bed the tabernacle on; and put the post back in.

And all for one problem that didn’t exist, and a new one I never knew or cared about until now.

The foam in the inaccessible void is still sodden, but Bob’s got a sowlution for that: ‘Simple, yow drills a hole in yow bottom of yow boat and yow water pours out.’

Well, sod my soggy bottom, I’m going sailing. Cost: ZERO.

As published in the Summer 2016 issue of PBO – now on sale!

Dave Selby’s 300-mile voyage in a Sailfish

Dave is calling for PBO readers to join in with his sailing adventure, to share their wisdom, cheer him along…

Blog 2: Dave Selby flees to Sardinia

I’m so daunted by the enormity of Marlin’s Mission I’ve fled to Sardinia to spend a week with friends on…

A racing uncertainty – Dave Selby’s Mad about the Boat

Not entirely sure if he has what it takes to become a competitive sailor, Dave issues a treatise on the…

The application of remorse code – Dave Selby’s Mad about the Boat

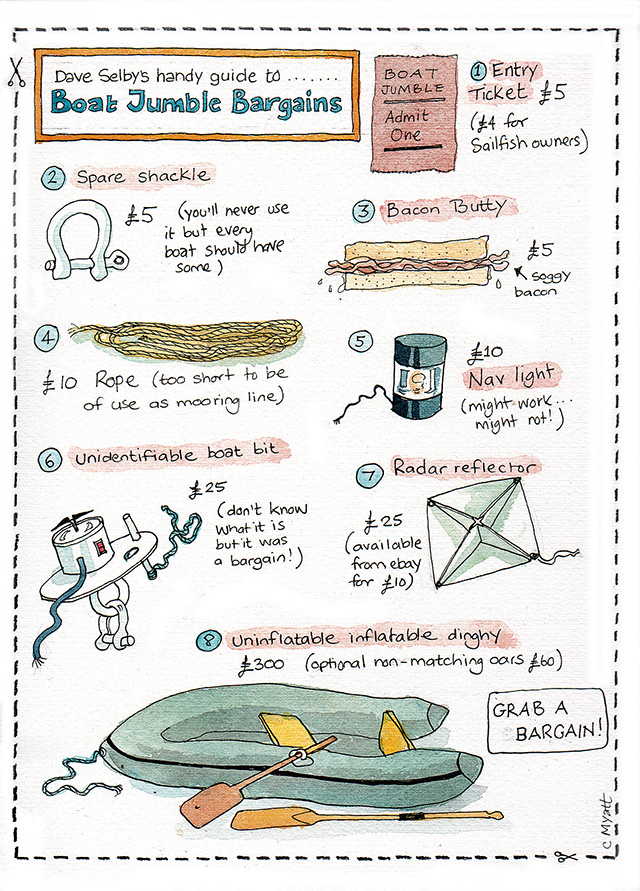

At boat jumbles, it would appear to be customary for buyers and sellers alike to feel hard done by, says…

My supply of ensigns dried up – Dave Selby’s Mad about the Boat podcast

Dave provocatively contends that an ensign can make a serviceable tea towel – and vice versa

The Firth dimension – Dave Selby’s Mad about the Boat podcast

When the movie circus rolls into town, Darcy-fanciers vainly search for Colin Firth – although PBO columnist Dave Selby and…

Full bed and boards – Dave Selby’s Mad about the Boat

PBO columnist Dave Selby discusses the prospect of opening a boatel...

The best kind of lock-in – Dave Selby’s Mad about the Boat column

PBO columnist Dave Selby shares a Lock and Bull story: a pub wasn’t a pub in olden times unless it…

Gracing us with their presents – Dave Selby’s Mad about the Boat column

To the seasoned observer, the sight of boutique branded sailor wear in the pub at this time of year signifies…

Walking off with a prize – Dave Selby’s Mad about the Boat podcast

Despite subscribing to a leisurely sailing ethos, Dave finds himself accepting a sailing prize. Which had been won by someone…

Berth control for men – Dave Selby’s latest podcast

Dave Selby describes the tortuous boat-handling processes which led to him being rear-ended by a pontoon

Hitch horror and trailer trauma – Dave Selby’s latest podcast

Dave Selby asks 'Why must boat trailers be such a drag?' in his latest column published in Practical Boat Owner…

Nelson’s fifth columnist – Dave Selby’s latest podcast

Dave Selby reveals a secret in his latest column, published in the September 2015 issue of Practical Boat Owner magazine.

Dave Selby podcast: ‘Mad About The Boat’

PBO columnist Dave Selby finds that a yacht club work day provides an opportunity to drink limitless cups of tea…

Dave Selby podcast: ‘Mad About The Boat’

In his latest boating podcast, Dave Selby issues a bewildered salute to those splinter group members for whom leaky wooden…

Dave Selby podcast: ‘Mad About The Boat’

Dave Selby explains the WC arrangements on a Sailfish to a keen novice sailor who speaks almost entirely in acronyms...