It’s like the boat-launching Olympics for Greg Manning as he leaps hurdles and avoids cutting corners to cover 1,920 miles back and forth in 15 days to get his yacht safely afloat...

Fairey Atalanta A142 Sugar Plum, being a mature lady, needs a lot of maintenance. Living in the north of Scotland, she’s stored over winter in a building for her protection from adverse weather and to allow maintenance appropriate to the temperature.

Her summer mooring is at Arisaig, a six hour drive from home, and so it’s essential that everything needed for her launch and commissioning is carefully checked and loaded before leaving home. I have an orange tidy tray for the small and unique items and a written checklist of both its contents as well as everything else needed.

In 2019 it was probably the 17th time I have prepared for the long drive and the launch. My friend, Steve, had volunteered to help. It was the first Sunday in June when we set off. Steve is a very practical person and always has his mind on the task in hand; I could not have asked for a better friend to help me.

With the boat’s internal sling we launched at Arisaig using a teleporter which is so much more convenient and cost-effective than a boat hoist. On the Monday there was only an hour between the boatyard staff being available and the ebb tide, leaving enough water to motor away.

We arrived on Sunday evening at 2000 in light drizzle and needed to get as much done as possible to be ready for the morning launch. The main task was to fit the rudder blade.

Article continues below…

How to launch a trailer sailer (and the key mistakes to avoid)

George was helping to launch his friend’s boat and asked if Paul and I could give them a hand. My…

Boat launch checks for getting back on the water

Launching your boat might feel a bit daunting, but these simple checks from insurance broker Steve Risk will ensure your…

Having ensured that the up and down haul cables were not crossed, I went to the orange tidy tray for the centre bush that the blade pivots on. It wasn’t in the tray. I searched the back of the Land Rover, I phoned home and my wife searched the workshop.

That bush was nowhere to be found. By now it was 2200 and there was only one thing to do. We loaded the rudder blade and its pivot bolt and set off back to Aberdeenshire arriving home at 0200 in the morning.

Steve and I both went to bed and were up again at 0730. Steve then drove the 30 miles to his house and turned a new bush on his lathe in marine grade aluminium and at 1400 we set off back to Arisaig.

The orange tidy tray and checklist

Arriving at 1800 we had the rudder blade fitted in 20 minutes and retired to the pub for a meal before turning in. The good news was that during the day it had been too windy to launch so we had lost nothing, much!

Take two

On Tuesday morning we woke early to fair weather and the boatyard staff hard at work, ready to catch up for the lost day.

Being a day later we now had an extra hour before the tide was too low and the launch went without a hitch, the mast was stepped and enough standing rigging secured to make it safe.

I watched the depth of water decreasing, 1.9m, 1.5m as we quickly loaded the remainder of the inventory. The engine started on the first turn of the key after the winter layup and we motored away to our out mooring in 1.2m of water.

Steve had commitments at home so tired and satisfied we set off for the long drive home. I’d like to say it was an uneventful drive but, being tired, I did discover that the ABS on my Land Rover worked. Luckily no one was hurt!

My son Edward, who lives in Australia, had called the week before to say he was coming over for a week and a sail was planned.

He arrived on Wednesday, the day after we got back from the launch and on Thursday we drove over to finish getting Sugar Plum in commission.

The weather was fine and by Friday midday everything was loaded, stowed, secured, connected and working.

Sugar Plum looking her best ready for the long drive to Arisaig

As a shakedown, we motored for 40 minutes out and back between the skerries that are the channel between the Arisaig moorings and open water. A satisfied father and son drove home because although the forecast was fair until Monday evening, I had to fly south on Saturday to attend the prizegiving of the Devizes to Westminster Canoe Race.

On Sunday with just 48 hours before strong winds were forecast, Edward and I drove back to Arisaig with the intention of an overnight trip to maybe the North Channel at Moidart.

We boarded, gas on, kettle on, electrics on, keels down, rudder down, sail cover off, dinghy secured, I opened the seacock for the engine cooling water, Edward started the engine and went to the stern to hoist the ensign and reported cooling water coming from the exhaust. Lifejackets back on and with the engine now warmed up, cast off and with Edward at the helm we set off.

I poured the tea, found the biscuits and as I joined Edward in the cockpit I heard a strange high pitched noise. We were both bemused and then I realised it was the audio warning indicating an engine over temperature. I clambered to the transom and there was the sound of a diesel dumper truck and no cooling water.

Rapid response

A quick dash to the cockpit and the engine was stopped, the sail ties were removed and the main hoisted. Had it been against the stop watch it couldn’t have been done quicker. There was very little wind and we ghosted towards the nearest free mooring.

I was trying to think what had gone wrong, hopefully just an obstruction in the water intake. 1.2 knots, 1 knot, 0.5 of a knot and with only 0.2 of a knot as we picked up the buoy.

I opened the engine hatch and there was that distinctive hot engine smell but no apparent damage. I loosened the cover to the sea water strainer and no water gushed out, in fact it was empty and I could see the gate valve of the seacock was in the closed position.

Left: The old seacock showing how little access there was between the skin fitting and the body of the seacock. Right: Strainer and seacock below it

Before a deeper investigation I felt we should be back on our own mooring a cable away. By now there was no wind, I contemplated a short burst on the engine but decided that manpower was the best option so with my little inflatable as a tug set off. Edward told me that I was pulling the two and half tons at 1.2 knots.

Once safely back on my mooring I could relax a bit. The seacock was of the gate valve type and the handle turned freely but did not open the gate. I pushed and pulled the shaft and eventually the gate must have opened enough as I could feel the body of the strainer go cold as the sea water entered.

Towing at 1.2 knots

The next task was to inspect the pump, and unsurprisingly, the impeller had disintegrated so a full strip down of the raw water system was needed to ensure there were no pieces of the impeller blocking any part of the system, especially the heat exchanger.

It was a fine day and with a fresh mug of tea we worked away well together. As a spare I had an old impeller that had been changed as a precaution the previous season.

When the engine was started there was a good flow of cooling water from the exhaust.

At this stage, I’m sure many crews would have then set off to make the best of the remaining 48 hours of forecast good weather.

The pages of PBO are filled with tales of crews putting to sea thinking they have rectified a defect.

As Edward and I are both professional helicopter pilots, we have a responsible attitude to safety and the only discussion was when and how to fit a new seacock.

We went ashore and negotiated with the yard when we could lift out to fit the seacock which was not until the following Thursday, after Edward had returned to Australia.

The good news was that the tide would be ideal to lift out in the morning, giving me the day to do the work and lift back in the following day. On the drive home, we stopped at Inverness and bought a new DZR ball valve to replace the gate valve-type seacock. I was a lot more confident that this would be a more reliable fitting.

Sugar Plum being launched the way Fairey intended, with an internal sling to correctly take the weight – at Whitehills a few years before this eventful launch

Do or die

The following Wednesday I was lucky that Steve volunteered to help me and we drove to Arisaig with the boat trailer.

Edward had taken a photo of the assembly which showed the access to be tight. I had all my plumbing wrenches and a newly bought thin adjustable spanner in the hope that something would fit in the confined space.

The evening was spent lifting the heavier items of the inventory off and preparing to remove the mast. Everything went smoothly the next day and saw Sugar Plum on her trailer by 1000.

Now came the tricky bit. I’d installed the skin fitting and seacock 17 years earlier and knew that I needed to unscrew the strainer and then the old seacock without disturbing the skin fitting.

I remembered that there were no lugs inside the skin fitting to hold it while tightening or undoing the seacock. Who makes these fittings with no consideration of how they will be fitted? I started by forcing the gate valve closed and filling the strainer with boiling water in order to expand the threaded joint.

Sugar Plum in commission and safely on her mooring at Arisaig

Steve was able to grip the seacock which allowed the strainer that was screwed into it to come off easily. Now the hard bit, I wrapped rag round the seacock and trickled boiling water on to it. Steve just managed to get grips onto the little threaded part of the skin fitting exposed while I used as much force as I dared to unscrew the seacock, but it didn’t budge.

Deep breathing, try again to no avail but then a do or die thump with the palm of my hand on the wrench and it came undone. Time to sit back and relax with a mug of tea before fitting the new DZR ball cock and reassembling everything. On inspection, the gate valve was found to have completely disintegrated internally with no sign of the circlip that located the shaft or the grove it was meant to sit in.

Next day, the relaunch went without a hitch before going home only to return two days later to get Sugar Plum back in commission. The start of the sailing season had taken 15 days and six journeys of 320 mile round trips between Aberdeenshire and Arisaig. The rest of the season was a bit more relaxed!

Lessons learned

- Don’t be complacent. I’d looked in my faithful orange tidy tray for the rudder bush and had mistaken a roll of insulating tape that looked similar. I should have actually picked it up and not relied on just looking.

- When checking the cooling water is flowing, make sure it really is. Edward had just seen residual engine water being discharged.

- Never put to sea without all means of propulsion prepared. In our case, the sail cover was off so hoisting the main took no time at all.

- Seacocks have a limited life, especially gate valve types. Inspect them regularly and change them as part of preventive maintenance rather than waiting for them to fail.

- Remove items like impellers long before needed and, if it is still serviceable, keep the old one as a spare – that way there is no chance of items not fitting due to mis-ordering, mis-identifying, mis-picking, mis-labelling, or mis-packing. Over the years, I’ve experienced all of these things with new automotive and aeronautical spares.

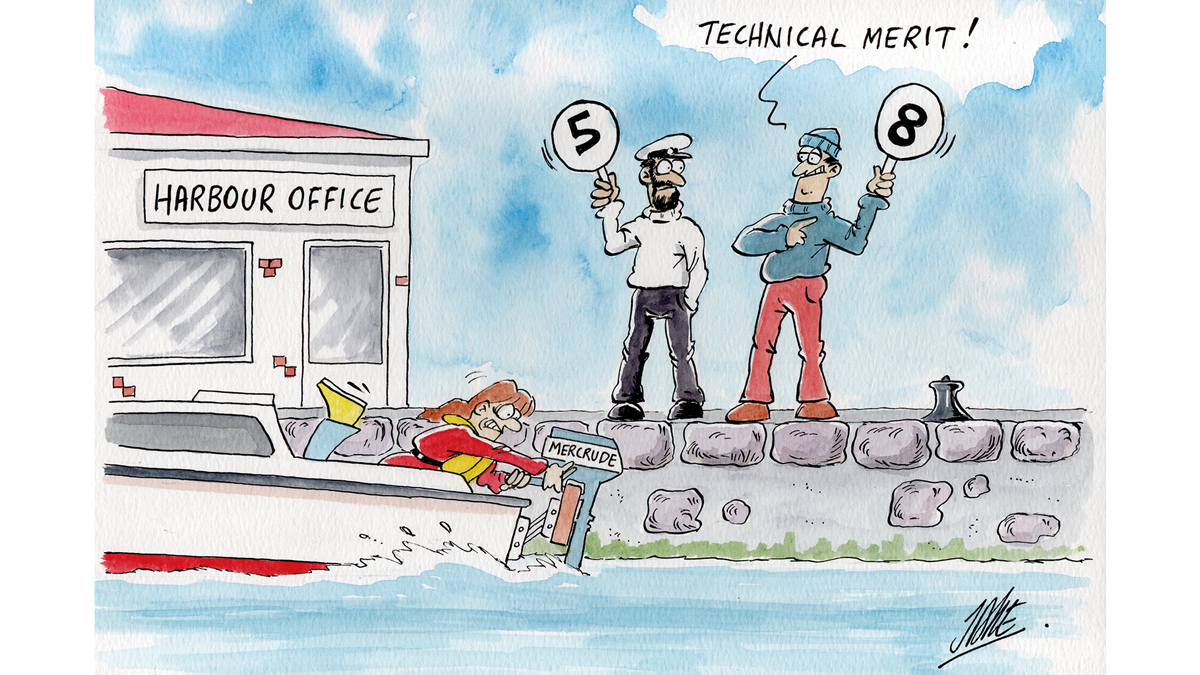

‘Too modest to mention’

Stuart Carruthers

Royal Yachting Association (RYA) Cruising Manager Stuart Carruthers responds: “Greg has identified a number of important lessons in his article.

“The marine environment is harsh, even DZR fittings have a life and impellers fail so a spare is always a good idea, as is knowing how to change it.

“However, the most important point which Greg is clearly too modest to mention is that as a pilot, he was not tempted to cut corners and to take risks.

“The prospect of a number of lengthy trips to put things right and do things properly would have tempted many of us to risk going ahead to make the best of a planned trip, and things could have quite easily have turned out for the worse.

“Safety is often described as a state of mind. A responsible attitude to safety is a lesson we should all consider.”

Email your boating experience story to pbo@futurenet.com. If it’s published you’ll receive the original Dick Everitt-signed watercolour which is printed with the article.

Why not subscribe today?

This feature appeared in the August 2023 edition of Practical Boat Owner. For more articles like this, including DIY, money-saving advice, great boat projects, expert tips and ways to improve your boat’s performance, take out a magazine subscription to Britain’s best-selling boating magazine.

Subscribe, or make a gift for someone else, and you’ll always save at least 30% compared to newsstand prices.

See the latest PBO subscription deals on magazinesdirect.com