Richard Stone mends his deck saloon's windscreen wiper motor

I sail a Degero DS331 which, having a deck saloon, allows me to stay out of inclement weather when sailing. However, it does require working windscreen wipers when it is raining or when taking sea spray over the bow, to keep a good lookout from the saloon.

Unfortunately, after 20 years of use, one wiper had begun to run slowly and finally stopped working altogether. A quick inspection showed nothing obviously wrong, and on removing the connecting arm, the electric motor spun freely, but it was impossible to move the shaft, which was seized solid.

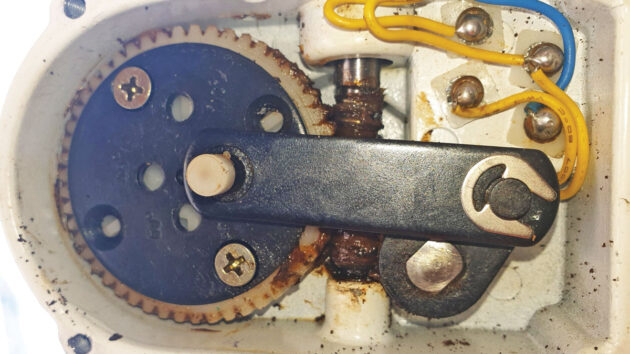

Shaft and housing cleaned and greased ready for assembly. Credit: Richard Stone

Assuming that salt had penetrated the outer shaft seal, I tried soaking the shaft in vinegar, but this had no effect – so the assembly would need to be dismantled to free the shaft. With the drive housing cover removed, I could see the drive arm was secured with a circlip, so that was the first thing to come off.

The end of the shaft had been peened over the short drive arm and was obviously not intended to be dismantled for servicing. Luckily, I have a small rotary tool on board, which I used to grind the end of the shaft down until it was flush with the face of the arm. This allowed me to hammer the shaft out with a drift.

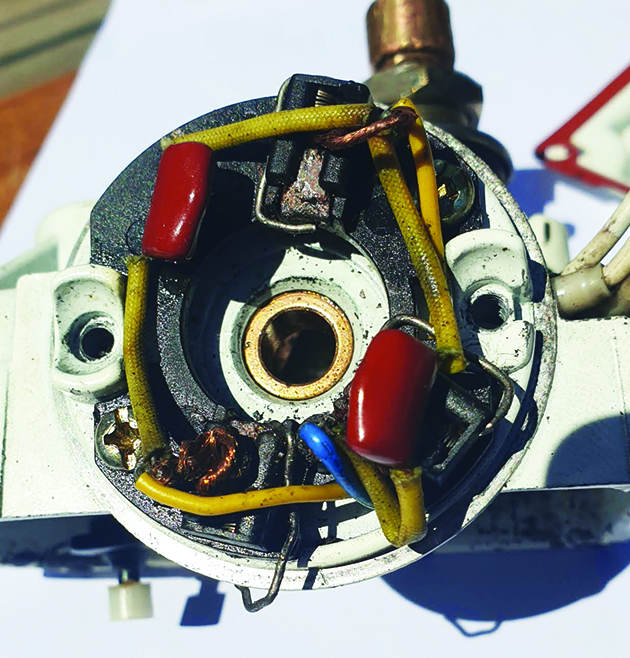

Carbon brushes held in place with wire clips for the windscreen wiper motor insertion. Credit: Richard Stone

With the shaft removed, a quantity of black dust fell out – possibly dried grease or dust from the motor bushes, which may have led to it jamming. With the shaft removed, I could now clean it and the plain inner bearings with vinegar before rubbing with fine wet and dry paper and lightly greasing before reinserting the shaft into the housing.

The hardest job was replacing the electric motor, which I removed so it was not contaminated with metal while grinding the shaft end. To keep the three carbon brushes pushed in against their springs while inserting the motor, I used wire bent into clips, which were easy to remove once the motor was fully inserted.

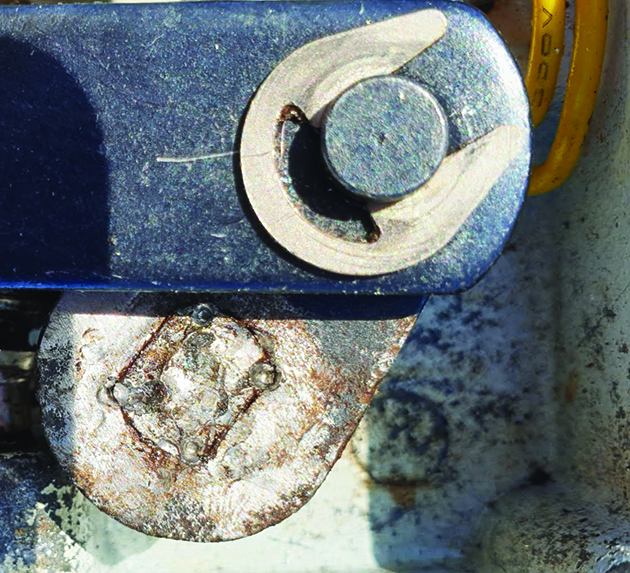

Four centrepunch dents held the arm back in place where it had been ground off. Credit: Richard Stone

On reassembly, in order to keep the arm in place on the end of the shaft, I punched the four corners. This has given sufficient resistance against the wiper arm spring to allow the blade to clear the screen properly.

The rebuilt wiper now works fine although, when the boat is laid up next winter, I’ll probably drill and tap the shaft end and insert a flat-headed retaining bolt so that I can easily service the shaft as and when necessary in the future.

How to restore a manual windlass as a DIY practical project

Part of PBO’s DIY from Home series: browse all related ‘in the workshop’ articles here I don’t object to the…

22 practical tips for a single handed sailor to make your boat easier to sail

Doctor Tom Miller shares some ideas to help make single handed sailing a safer and more comfortable experience

Boat wiring explained for the practical sailor

Pat Manley and Oliver Ballam demystify boat electrics and explain wiring and the best techniques for its installation

Rig tuning: a practical guide for sailors

Correct rig tension will maximise the efficiency of your boat’s sails as well as reduce stresses on the mast. David…

Want to read more articles like Boat windscreen wiper motor repair: how one boat owner fixed the seized motor?

A subscription to Practical Boat Owner magazine costs around 40% less than the cover price.

Print and digital editions are available through Magazines Direct – where you can also find the latest deals.

PBO is packed with information to help you get the most from boat ownership – whether sail or power.

-

-

-

- Take your DIY skills to the next level with trusted advice on boat maintenance and repairs

- Impartial, in-depth gear reviews

- Practical cruising tips for making the most of your time afloat

-

-

Follow us on Facebook, Instagram, TikTok and Twitter