Stu Davies takes us back to basics and advises on how to change oil, fuel and air filters on your engine

Part of the engine winterisation regime is changing the oil and filters and doing certain checks and adjustments.

Filters on our boat’s diesel engine are the oil filter, the fuel filters and sometimes an air filter.

Filters are used to stop foreign material entering the engine whether by air or fuel and to clean the circulating engine lube oil of carbon and other combustion products.

In the early days of internal combustion engines they were simple devices, basically used more as a screen to take out large particles.

Today, filters are more sophisticated, manufactured with modern high-tech ‘paper’ materials and are engineered to take out particles as small as 5 microns.

You don’t necessarily need to use original equipment manufacturer (OEM) boat engine filters; cheaper ones from established suppliers can be just as good. Credit: Stu Davies

It is worth noting that mainstream filters from non-OEM suppliers are just as good as the branded ones offered by main dealers.

Filters come in all shapes and sizes and means of attachment to the engine.

In the 1970s, many manufacturers went down the route of metal-encased spin-on filters.

Previously they were paper filters, placed inside a removable metal can. Both oil and fuel filters were made like this.

Today, manufacturers generally use ‘paper’ filters which are encased in a plastic housing and threaded onto an oil manifold on the engine block.

Removal of the old engine filter

Removing a filter, whether it be an oil or a fuel filter entails figuring out what type you have.

For example, my old-fashioned, Volvo Penta MD22 has a spin-on metal can oil filter and a similar secondary spin-on fuel filter.

Usually too tight to undo by hand, you can use a proprietary tool to grip the spin-on oil and fuel filters to remove them.

There are many types of tools available. I have two.

One is a ½in drive socket tool with a textile adjustable belt which can be fitted over the filter canister and adjusted to size. It’s a good tool but it gets difficult to work if the filter is fitted tightly or where heat has made it tight.

Ratcheting tighter with a ½in drive ratchet takes up a lot of slack and sometimes the stretchiness of the belt doesn’t allow maximum force to be applied to unscrew it.

A steel strap filter wrench. Credit: Stu Davies

The second tool is a metal adjustable flexible metal band type. The drive band is basically like an old clock spring with an adjustable mechanism and handle attached to it, that can be adjusted to fit the filter.

When the tool is rotated, the edge of the adjuster digs into the filter can to grip it and turning it undoes it.

A lot of people get confused here about which way to turn to undo it.

With it being vertical, transposing the righty tighty, lefty loosy rule seems to confuse them and they end up tightening the filter!

You do need good access and space to use it.

There are many other tools available with some proprietary ones fitting the base of the filter, rather like a large ring spanner.

However, the different manufacturers use different sizes so you end up buying lots of them.

A strap-type wrench ready to go on an engine filter. Credit: Stu Davies

Another type is an adjustable one with fingers that can be adjusted to suit the flats on the bottom of the filter; again, this can be difficult to use in a confined space.

Sometimes a good, strong hand can undo them but this applies more to fuel filters which don’t run as hot as an oil filter.

In the worst-case scenario where they don’t want to come off then a screwdriver punched through them and used as a lever is acceptable.

Punch the screwdriver through the can near the flange where it is strongest – but avoid the centre where you might damage threads – and make sure you have enough ‘swing’ room to turn the canister with the screwdriver as a lever.

If this fails you can use a big screwdriver as a chisel on the filter flange; tap it with a hammer and it should turn.

But be careful, as if you get this wrong it will be financially painful.

Engine filter care: Replacing seals and rings

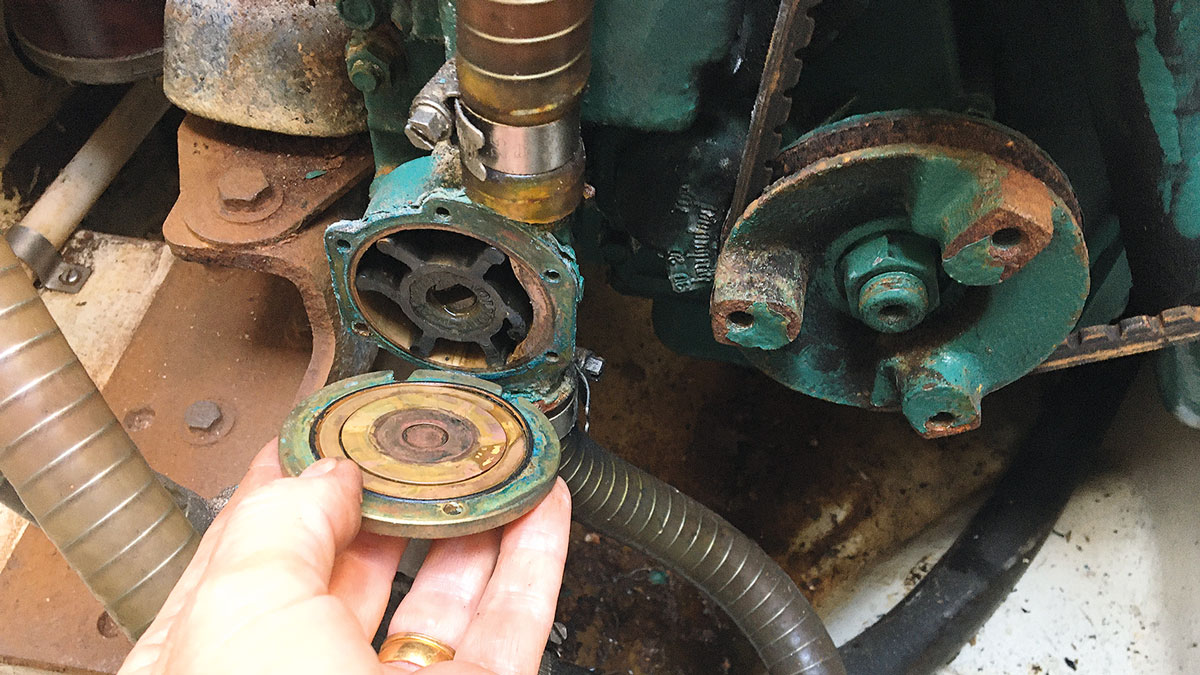

Filters like the CAV 296 type are held together by a small bolt through the middle.

Undoing it allows the ‘stack’ of components to come apart and the metal can filter to be replaced.

Simple single-cylinder engines can have bowl-type fuel filters, again held together with a single bolt.

The important thing about these filters, indeed all filters, is to ensure that rings and seals are replaced or, in the case of can filters, that the embedded seals are the correct size, ie they ‘land’ on the machined faces of the filter housing.

The CAV ones have been in use since I was an apprentice 60 years ago. They have multiple O-rings in the stack.

An embedded sealing ring on an oil filter. Credit: Stu Davies

Make sure they are replaced and are in position. I use grease to hold them in position while building the stack.

Don’t overtighten the single bolt which holds them together either!

The head of the bolt is 7/16in AF but an otherwise rarely used 11mm spanner will do it.

Bowl filters usually have a seal in the housing that the bowl fits in to.

Ensure that a new seal is fitted here. Use grease or Vaseline to hold them in place while assembling them.

Spin-on oil filters always need a smear of oil on the embedded sealing ring to allow easy tightening of them.

Engine filter care: Hand tight is best

A strong hand is good enough to tighten spin-on filters. Don’t use a tool unless absolutely necessary.

They can distort the can and cause internal damage to the filter inside.

More modern engines use plastic filter cans with replaceable ‘paper’ filters inside.

They usually have a large ‘nut’ formed on the bottom of the housing and a ½in drive socket can be used to undo these.

Flats on the base of an oil filter can be gripped by a specialised wrench. Credit: Stu Davies

The ‘paper’ filter element inside is usually gripped on the inside of the middle section by a ‘finger’ on the engine oil manifold.

It holds it in position while the housing is screwed back on. They have a coarse plastic thread on them with an O-ring groove to seal them.

Always use a new O-ring and smear some oil on the threads when reassembling.

It can be quite deceiving when tightening the plastic can.

It seems to go on for quite a while but when it comes to the end of the thread it is quite obvious and a good nip on the socket is sufficient to finish tightening it.

Air filters

Air filters on our boats are not very sophisticated; more like strainers than anything.

My MD22 has just a bowl filled with wire wool as a ‘filter’. My previous boat had a Volvo Penta MD2030 engine and this had just a piece of metal with 2mm holes in across the air inlet!

In these cases, a simple clean of the medium with diesel fuel and then some engine oil drizzled on to them was sufficient. The engine oil is there to trap dust.

Some engines have slightly more sophisticated systems and a search of the manufacturer’s maintenance instructions will let you know what to do with them.

There is one other place a filter can be fitted and that is in the stack pipe that goes in the fuel tank that picks up the fuel that is sucked in by the lift pump for the diesel injection system.

It is usually a piece of cylindrical gauze soldered to the bottom of the pipe and can be a source of great puzzlement as owners wonder why their engines don’t perform properly.

If your engine and fuel tank have one of these in the system this is the first place that diesel bug will start to block.

If your system does have one fitted, check it every once in a while and make sure it’s clear.

How to winterise a boat engine

Engineer Stu Davies explains the steps you should take to make sure your boat’s engine is protected over the winter…

How to change a water pump impeller

Stu Davies shows you how to check and replace an engine’s raw water pump impeller, and explains why it’s an…

How to service a marine diesel engine in 12 simple steps

It was time to service the marine diesel engine on our Maxi 84 cruiser. Knowing how to diagnose and fix…

How should I look after my fuel to beat diesel bug?

Ali Wood gets some bug-beating advice from Marine 16’s Peter Weide and learns why modern diesel requires more attention than…

Want to read more practical articles like How to change a boat engine filter?

A subscription to Practical Boat Owner magazine costs around 40% less than the cover price.

Print and digital editions are available through Magazines Direct – where you can also find the latest deals.

PBO is packed with information to help you get the most from boat ownership – whether sail or power.

-

-

-

- Take your DIY skills to the next level with trusted advice on boat maintenance and repairs

- Impartial in-depth gear reviews

- Practical cruising tips for making the most of your time afloat

-

-

Follow us on Facebook, Instagram, TikTok and Twitter