PBO reader Chris Marden wants to know if he can repair the outer case of his boat heat exchanger with epoxy. Stu Davies has the answer!

Can you epoxy repair an aluminium boat heat exchanger?

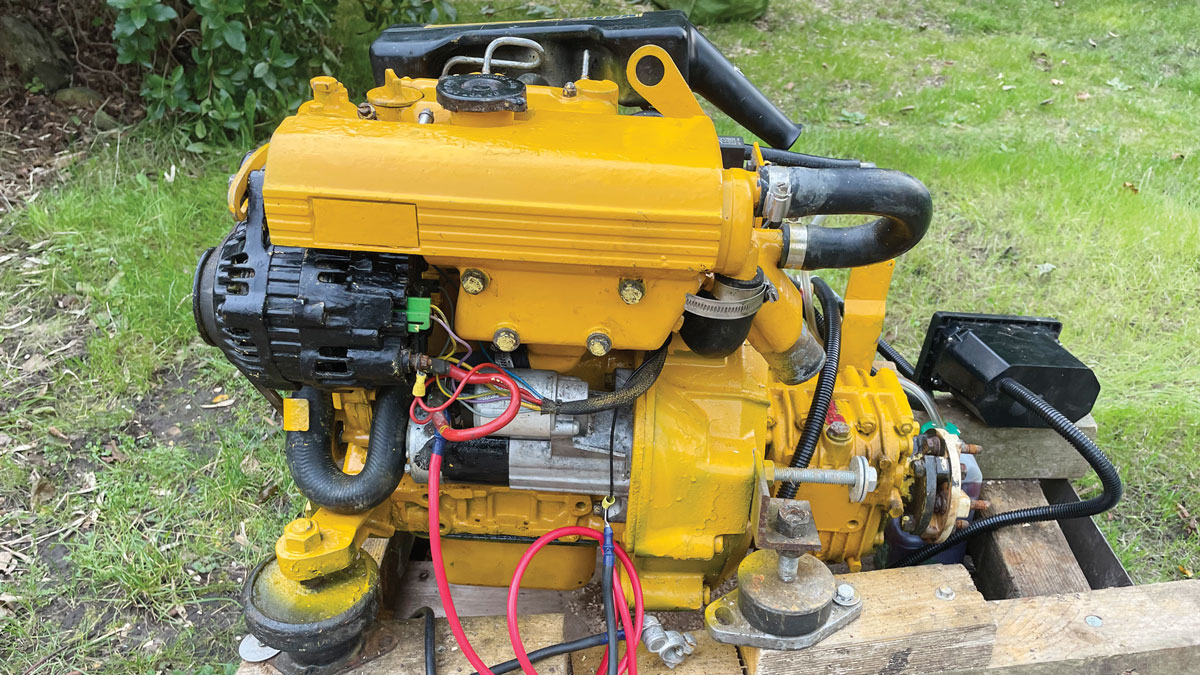

The Volvo Penta MD2030 and MD2040 marine diesel engines are popular in many of our sailing boats including my own Dufour 40.

But I became concerned when our local chandler was asked to replace the outer boat heat exchanger case of one such engine because it had sprung a leak due to corrosion; an especially nasty surprise for the owner to discover this part is no longer made.

My concerns were heightened when a skipper alongside told me a friend of his had the same 40th anniversary model yacht as mine and had suffered exactly the same problem with his heat exchanger case.

The Volvo Penta MD2040 in Chris Mardon’s Dufour 40. Credit: Chris Mardon

It has put me to thinking about how a leaking, cast aluminium case could be repaired.

Although my boat heat exchanger is not leaking there is the possibility that when it does the whole engine will be a write-off.

There will be many MD2030/40 owners who might appreciate a cheaper but effective solution. Would these proposed epoxy repair steps work, I wonder?

- Drain, remove and clean the interior of the boat heat exchanger casing with a complete wash out. But what is the best chemical to clean its interior back to bare metal?

- Put it into a warm oven for an hour to thoroughly dry it out.

- Cover all the water jacket holes except the filler with strong adhesive tape. Prevent the filler cap from sticking down with masking tape over its rubber seal.

- Measure the outer dimensions of the casing to determine its area in square millimetres and multiply it by 2mm thickness (say) to determine the volume of resin that would be required to thoroughly coat the inside of the case.

- Mix the resin and hardener, pour it into the filler hole and close it up. Now rotate the case over and over so that all interior surfaces will be thoroughly covered in resin. Continue rotating until the resin in your mixing cup has set. Leave to harden and fully harden overnight. The cure time for the resin is fairly critical. Too long will leave the holder rotating the case until his arms are dropping off. Too quick and the resin won’t have time to cover all surfaces.

- Remove the filler cap and all the adhesive tape and carefully cut out the hard resin where it has blocked the waterways. A rounded file will help to clean the resin back to flush with the casing’s edges.

- Reassemble the casing to the engine with new gaskets, fill it with recommended coolant and run the engine for a while to check all is well and leak free.

The success of this process would depend upon the resin sticking permanently to the interior surfaces of the heat exchanger casing when flooded with coolant at 80°C.

Clearly, the cleanliness of the aluminium and the type of resin will be critical, but if it has a good chance of working it could save many boat owners from a very expensive engine replacement.

Chris Mardon

Stu Davies replies:

Sadly I don’t think this idea will work. Aluminium is very difficult to stick stuff to, it oxidises easily and that oxide is the issue.

Epoxy resin will not stick to it very well and the slightest breach in the coating will allow water in and corrosion will carry on underneath the resin.

And cleaning it thoroughly internally to apply a resin would almost be virtually impossible.

The oxide is also why it is tricky to weld and why the TIG system is used to weld it.

There are two issues that I have heard of regularly about Volvo Penta MD intercoolers.

A long-term engineering solution to heat exchanger corrosion is to have new aluminium TIG welded in

The first is where the brass radiator cap housing is pressed into the alloy intercooler and it comes loose because of corrosion.

The second is where corroding through at the exhaust outlet happens and is usually caused by owners not keeping their coolant/antifreeze in top condition.

Antifreeze is not only for preventing frost damage, it also contains corrosion inhibitors.

Blocked exhaust elbows can contribute to this issue by allowing hot sea water to splash back from where it is injected into the exhaust close to this area.

Continues below…

Diesel engine heat exchanger and manifold repair

Barry Pickthall explains how he carried out engine repairs on a budget after a couple of years of Covid-19 lockdown…

Smoking boat engine? Our expert explains what could be wrong

Gunter Bock from Norway writes: “I read in PBO’s November 2021 issue about exhaust elbow problems. You recommended replacing the…

How to: change a marine diesel water impeller

One of the key checks when you start up your engine is that your raw water cooling system is working…

New manifolds are not available, however supplier parts4engines says it may be able to source some Perkins M30 ones which should fit the Volvo Penta MD2030.

As a temporary fix to get you home, careful mechanical cleaning of the exhaust port area where the elbow bolts on and the judicious use of JB Weld (a metal repair epoxy) is a good fix.

But what about long term?

The radiator cap brass neck pressed into the boat heat exchanger can be teased out, the area cleaned well mechanically and a new aluminium neck can be sourced to weld in to the casting. parts4engines sells a kit to do this, or any good car radiator repair shop will know what you’re after.

Mechanics use them to repair aluminium car radiators.

New metal can then be resurfaced and cleaned up to the unit’s original dimensions

Exhaust ports: I have seen YouTube videos of a German guy milling off the affected parts on an MD22 heat exchanger back to good metal and then careful TIG welding in of new alloy in the area.

This is the gold standard and produces a permanent repair. Superb results can be obtained from a good machine shop and a skilled TIG welder.

To sum up, I’m of the opinion that the exhaust elbow where the raw cooling water is injected to cool the exhaust and get rid of it is a maintenance item – it needs checking every five years or so.

The fresh water cooling system needs its antifreeze/inhibitor liquid checked and changed regularly to avoid affecting the aluminium casting and also check that the correct antifreeze is being used – glycol-based for older engines and OAT for newer ones.

Check your spec!

Enjoyed reading Can you epoxy repair an aluminium boat heat exchanger?

A subscription to Practical Boat Owner magazine costs around 40% less than the cover price.

Print and digital editions are available through Magazines Direct – where you can also find the latest deals.

PBO is packed with information to help you get the most from boat ownership – whether sail or power.

-

-

-

- Take your DIY skills to the next level with trusted advice on boat maintenance and repairs

- Impartial in-depth gear reviews

- Practical cruising tips for making the most of your time afloat

-

-

Follow us on Facebook, Instagram, TikTok and Twitter