Thinking about an ocean passage? PBO’s Laura Hodgetts shares some tips from sailors setting sail with the 30th ARC

Top tips from Jerry the rigger

Jerry Henwood, aka Jerry the rigger, up a mast. Credit: Clare Pengelly

Jerry Henwood, aka Jerry the rigger of Gosport, has worked in the rigging industry for more than 25 years and is the ARC official rigger.

Jerry and his right-hand-man Ross went up 100 masts in the run-up to the ARC 2015.

Here’s his rigging checklist:

- Ask ‘Is my rig up to this trip?’ before leaving the UK. The answer will probably be yes, but get a professional rigger to check the mast and rigging. Remember, the more you know about your rig and how to spot faults, the safer you will be! Tell him that you are going to do the ARC and ask what he can suggest to make your rig easier to sail on a long downwind leg.

- Make daily rig inspections while under way – part of this is looking aloft through binoculars. This should include going aloft periodically for an up-close inspection. One missing or damaged split pin could be enough to bring down a rig. A split pin is only working properly when both of its legs are open by a minimum of 20°.

- Format a check sheet. Methodically start at one point on the vessel and work your way around. Once you are happy that all is OK at deck level, then it’s time to check aloft. When you’re halfway across the Atlantic, that isn’t the time to learn how to climb a mast! Practise in the marina with your crew on a calm day, then try it on a windy day. Then add rain.

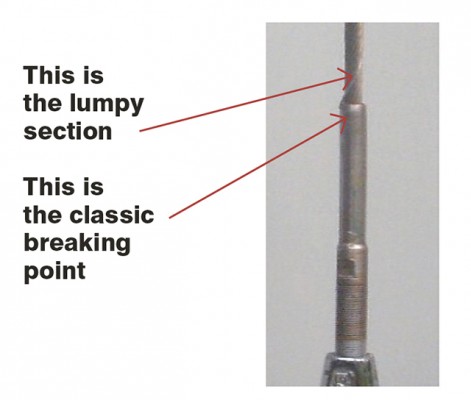

- Check your standing rigging wire where it enters the swage. The most common place for standing rigging to break is just inside the swage: you can’t always see it, but you can feel it. Run your hand over the wire for about 100mm to 150mm above the swage. Push each strand in turn: if it moves, it is broken. If you are in port, have the wire and the opposite wire replaced. We replace in pairs to keep the rig balance correct.

- Check the shrouds. Look at the mast, boom and spreaders and the areas where anything joins, exits or is just attached. It should all be smooth with no cracks. All fastenings must be tight and secure.

- Key rings. It is essential that these are taped up so that anything passing over them (ropes, clothing, sails, etc) does not catch on them and pull them open.

- Lubrication. All moving parts should be able to move! If they don’t, start with hot water. They may be just seized up by salt and general dirt. If this doesn’t work, move onto penetrating fluids. Lastly, dismantle the item.

- Winches require looking after. Dismantle the winch. Lay the parts out on a clean cloth in the order of removal. Thoroughly clean each piece. Check its condition, look for cracks and chips. Replace any part that is damaged, paying particular attention to the springs and pawls. Smear a thin coating of winch or gear grease onto all the surfaces, regardless of whether they come into contact with another part. Reassemble. Test. When carrying out the winch service, always replace the springs with new ones. Each spring is very small and only costs about 35p.

- Check the boom. The part most often found at fault on a boom is the nylon wear washer that goes between the boom gooseneck toggle and the mast bracket. You may not have one; it will have worn away! Check all of the fittings that are attached to the boom.

- The spinnaker pole. Make sure that the piston ends are freely moving. Check the trip lines for chafe. If you have a telescopic pole, make certain that the telescopic section slides freely and that the locking parts are in good condition.

- The boom preventer. When sailing downwind, there is a risk of an unintentional gybe. You should use a boom preventer line. This line must be led from the aft end of the boom forward through a block and back aft. If you place the line further forward on the boom, you will break the boom if you broach. It will also help when the boat is rolling in a big swell and/or light winds.

Preventers should be rigged to the end of the boom

- Wire cutters. When the worst happens and the rig has fallen down, you need a really good set of wire cutters (not bolt croppers). Go to see your local rigger and look at his cutters. Try them on an old piece of wire that is the same diameter as your largest wire, then imagine that the deck is rolling about. Are you or your crew strong enough to use them? These aren’t cheap to buy, but are an essential safety item. Remember, a mast can quickly knock a hole through the side of a yacht: either get the mast back on deck quickly so that you can make a jury rig, or get rid of it.

Seize shackle pins to prevent them from working loose

- Rigging repairs at sea. As soon as you notice a problem with the standing rigging, make the problem side the lee side of the rig. Brace the mast with spare halyards and then drop your sails. Do not let your sail flog. There are three main methods of repair. Carry a spare set of rigging; carry some lengths of wire and a supply of bulldog grips; use these to bridge the damaged area, or carry a set of Sta-Lok rigging repair terminals.

- Always wear a helmet when climbing a mast at sea.