Is it worth buying a boat with a non-running engine? Vyv Cox has some tips on what to look for before deciding if it’s a viable project

How do I tell if an old boat engine is beyond repair?

Although the cost of new boats has reached levels that put them out of reach for the majority of us, it remains the case that there are many second-hand vessels on the market.

Some of them may be only a few years old, needing little attention to put back into service, whereas at the other end of the scale there are plenty of very cheap boats, sometimes abandoned for a variety of reasons, others sadly lacking attention and now no longer required.

It’s usually the case that the hull and interior can be assessed visually but other parts, particularly the engine, are not so straightforward.

It’s common to come across a boat languishing in a yard somewhere after its engine ceases to function for some reason, and the boat is offered for sale at a low price.

Extensive damage such as this, in which a failed connecting rod punched a hole through the crankcase, would almost certainly lead to write-off

A potential boat buyer must decide whether to walk away or take a chance that the engine, whose total replacement cost could be in the region of £10,000, might be salvageable.

Here we’re aiming to assist that buyer’s decision, but it’s also useful information for an owner whose boat has been laid up for a long period of time.

It goes without saying that uncovering major problems at any stage of the investigation may well be sufficient cause to abandon and look elsewhere.

Bearing in mind that no seller wants their boat’s engine to be stripped for inspection, he or she may well be amenable to some limited investigative work in order to secure a sale.

Hopefully some agreement can be achieved between the two sides that will allow a small amount of work to be carried out.

There’s a strong likelihood that either there’s no battery in the boat or that it no longer functions, so the potential buyer will need to have one available assuming the preliminary assessment is positive.

He or she will also need a few tools such as spanners, screwdrivers and the like.

Initial assessment of the old boat engine

First, carry out a thorough visual assessment.

Sometimes it’s very obvious that the engine has suffered a catastrophic failure, in which case the desired answer has been achieved very quickly.

It’s also worth checking at this stage that there is some oil in the sump, that the oil filter is in place and that no external oil pipes have been cut or disconnected.

Make an initial visual inspection, remembering not all faults are obvious. Make sure there’s oil in the sump. Credit: Theo Stocker

If there is obvious water in the sump it is probably better to abandon right away, as few engines will survive long term flooding without considerable damage.

Assuming nothing obvious can be seen, the work can start.

The very first test that needs to be carried out is to try to turn the engine over manually.

This can be done on many engines by using a socket spanner on the crankshaft pulley nut on the front of the engine.

Turn clockwise virtually as hard as you like but anticlockwise fairly gently to avoid undoing the nut.

On some engines, Bukhs and older Volvos, for example, there is no crankshaft nut but there is a large flywheel that can be turned.

Why won’t an old boat engine turn?

There can be several reasons why an engine won’t turn over.

Severe mechanical damage is one, such as a broken connecting rod.

In this case, it may be possible to partly turn over in each direction but not a full 360°. A valve may be stuck down, also preventing a full 360° turn but this can be seen by removing the rocker cover and inspecting the rockers while attempting to turn the engine over.

Possibly the most likely cause is that water has entered the engine and rusted the rings to the bores.

In the worst case the engine will not turn over at all in either direction, although judicious tapping with a hammer on the spanner may start it moving.

The nut on the crankshaft pulley is visible, about 25mm across the flats, requiring a comprehensive socket set. The water pump is driven by its own belt, lower left. It would be worth removing this before trying to spin the old boat engine. Credit: Vyv Cox

If it is possible to inject some paraffin or penetrating fluid into the bores via the injector ports, the situation might improve but this may be beyond what is allowed during a condition assessment.

Once the engine moves a small amount, turning first one way and then the other may eventually succeed in loosening the rust enough for full rotation.

An engine is unlikely to recover from this problem unaided, and the new owner will need to budget for a total strip-down, clean and maybe new piston rings and even a rebore or liners.

Once the engine is turning over fully by hand it’s time to try the starter motor.

Engine being hoisted into a boat for installation. The engine can be turned over by rotating the flywheel by hand

In a boat that has stood a long time unused, possibly flooded but inevitably in a good deal of moisture, there is a strong risk of electrical problems and short circuits.

The condition of the wiring needs to be checked very carefully before connecting a battery and, if necessary, the main supply to the panel should be disconnected, leaving only the large cable to the starter motor connected.

In this case the solenoid will need to be activated remotely, as will be explained.

It’s also worthwhile checking the earth connection, usually between the engine block and the negative terminal of the battery.

At this stage it is preferable not to supply cooling water to the pump.

Continued rotation of the engine and pump can cause back-flooding from the exhaust trap that will fill the engine through the exhaust valve(s).

Even in the event that the engine starts, it will come to no harm without water for a few seconds.

Longer periods of running will lead to the burning of plastic and rubber exhaust components and should be avoided.

Removing the pump impeller before extended starter motor operation is advisable.

Starter motors come in two types. Older engines such as the earlier Bukhs had Bendix types, whereas later ones mostly have pre-engaged versions.

These are easily identified as the pre-engaged type has a cylindrical solenoid attached, whereas the Bendix does not.

Continues below…

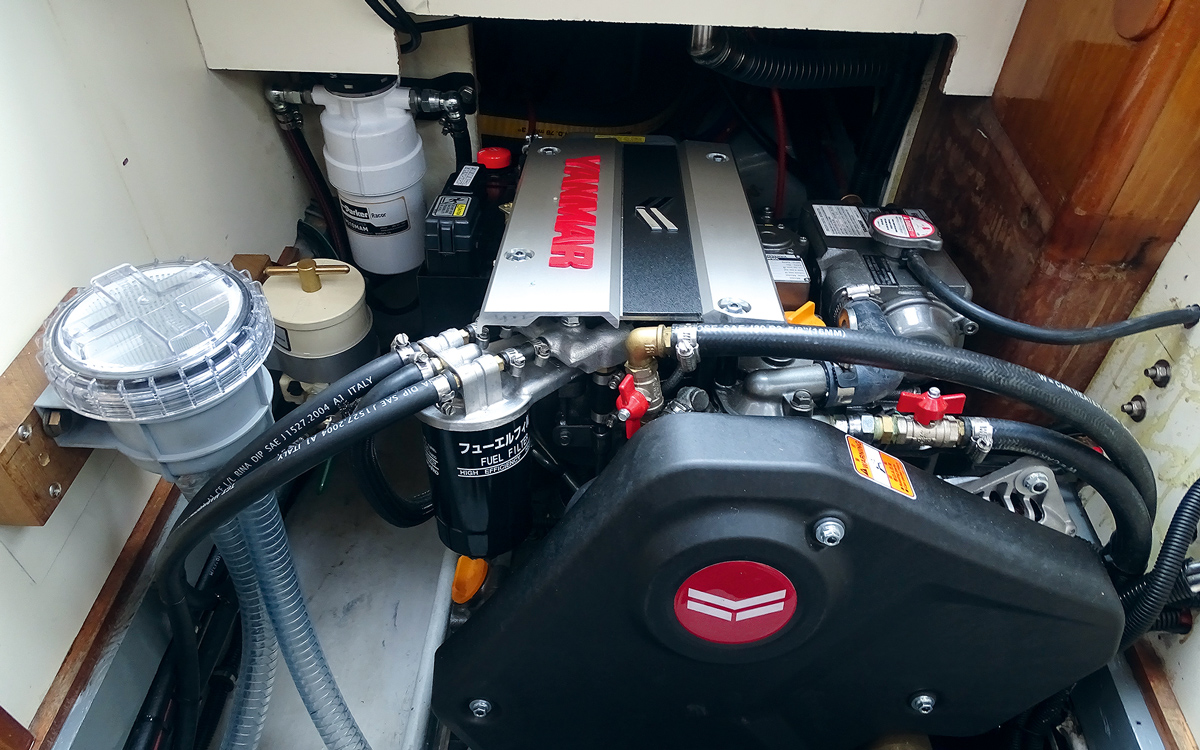

How to install a common rail diesel engine on a boat

Late evening turned to night as Pippin fought adverse tides off Corbière, hard on the wind, her old Yanmar straining…

How to service a marine diesel engine in 12 simple steps

It was time to service the marine diesel engine on our Maxi 84 cruiser. Knowing how to diagnose and fix…

Engine health check: 6 steps to make sure your diesel is in fine fettle

An idea struck me when I ordered an oil analysis for Merlot, my lockdown project boat. Routine health checks are…

Petrol or diesel, inboard or outboard: which boat engine is best?

When it comes to a boat engine, which is best? Petrol or diesel, inboard or outboard? Stu Davies answers your…

When the Bendix type is activated the motor turns and the pinion is thrown forward along the shaft by a coarse screw thread to engage with the starter ring.

This is a somewhat brutal operation resulting in noise and high wear of the pinion and ring gear teeth.

There is also a tendency for wear debris and oil to accumulate on the motor shaft, sometimes preventing the pinion from moving into the mesh.

Cleaning the shaft will usually solve this problem. In the pre-engaged starter, the pinion is thrown forward by the solenoid before the motor turns.

Only once the pinion has engaged with the starter teeth does the motor begin to rotate.

Even in regularly used boats there are sometimes failures of pre-engaged starters due to high resistance in the wiring.

Turning the key can result in clicking at the solenoid but no rotation of the engine.

The easiest way to solve this, and the only way if the wiring has been disconnected as suggested earlier, is to connect the solenoid directly to the power source, either with a short length of wire or in many cases, a screwdriver.

The solenoid terminal is usually, but not always, a 6mm spade type and the power input from the battery is normally a crimped ring terminal bolted to the end of the solenoid.

Connecting these two together briefly will spark but hopefully will also result in rotation of the engine.

It can happen that the solenoid can be heard operating by a solid clicking when the connection is made, but even after the pinion engages with the ring gear, the motor does not turn.

This is usually because the electrical contacts inside the solenoid have corroded.

If the solenoid can be disassembled the contacts can be cleaned up with a file but, if not, the only answer is to have the motor repaired or replaced.

A further problem on old boat engines in marine environments is that the heavy wire between the solenoid and motor corrodes and oxidises very badly, crumbling when touched.

Further activity

At this stage it’ll be known whether the engine has any major faults.

If it has turned over a number of times, and assuming that oil has been circulated to some extent, it should be possible to assess the presence or absence of compression.

Diesel engines have far higher compression ratios than their gasoline equivalents, making them quite difficult to turn over by hand.

As each piston approaches top dead centre (TDC) on the firing stroke it will take appreciable effort to continue turning.

At this stage it is comforting to know that this compression exists, as it tells us a lot about valves, rings and bores.

Even if less than hoped for, all is not lost, as improvement is not difficult or expensive.

The pinion in its resting position. When activated it slides along the shaft, rotating when engaged with the ring gear. Credit: Vyv Cox

Although there is a long way to go before it will be running reliably, the likely cost of any parts needed is an order of magnitude less than if it was totally seized or completely wrecked.

Further investigation is now dependent upon the goodwill of the current owner, as we enter a stage that is beyond simple surveying and general inspection.

Assuming the necessary agreement has been reached it is now possible to attempt to get it to run.

If the compression is very low or non-existent it’s worth checking valve clearances at this stage in case the clearance has been lost or a valve is stuck open.

The starter motor with its solenoid is seen at the front of this sad-looking engine, located to engage with the flywheel ring gear. Credit: Vyv Cox

Turn the engine over and check that all valves depress and return fully.

Hopefully this will improve the compression but, if not, piston damage may be indicated.

The essentials at this stage are uncontaminated oil, good fuel and a well charged battery.

The oil may be assessed by inspecting the dipstick, by drawing off a sample using a vacuum pump, or simply by a total change.

This will depend upon the level of commitment to the project.

For assessment purposes an oil change may well be a step too far, in which case the oil in the crankcase will have to suffice – but not if it contains appreciable amounts of water or appears to be partially solidified.

Fresh fuel required

It’s highly unlikely that fuel found in the tank of a boat that has stood unused for years will be in sufficiently good condition to start an old boat engine after a long lay-up.

The only answer is to supply fresh fuel, perhaps from a bottle or can with a temporary hose to the lift pump.

If the pump can be operated by a manual lever, it will be well worth bleeding the whole fuel system through as far as possible to expel any old fuel.

Easy-Start spray has a reputation that engines allegedly acquire a ‘taste’ for it, but my experience is that it’s invaluable on occasion.

Also check the air supply, ensuring that any filter installed is not blocked or damaged in such a way that debris, insects or other solids can be drawn into the engine.

Filter assemblies and manifolds have a tendency to rust, so a little cleaning may be necessary.

Next, ensure the electrical wiring is in good condition, either by careful inspection of what exists or by providing temporary connections to the essentials.

The components of a pre-engaged starter are shown in this diagram. In its normal resting position the pinion rests in the withdrawn position, pressed back by a spring

(not shown)

A diesel engine has no electrical requirement for operation but it will be beneficial to start it by operation of the switch or key on the main panel.

It will be essential to view warning lights, the oil pressure switch and/or audible warning in particular.

This warning light should extinguish while the engine is turning over on the starter motor, with the decompression switch operated if necessary.

On some engines, generally those without a cable-operated stop control, there will also be a fuel solenoid that needs to be activated to allow fuel to the pump.

It may take extended turning over with the starter motor before an old engine starts.

It’s best not to keep turning for more than about 15 seconds each time to prevent overheating of the motor windings.

After repeated unsuccessful attempts, it’s worth checking that fuel is getting to the injector(s) by slackening off the fitting on the top and turning the engine over.

When electrical current is supplied to the solenoid the coil is energised, causing the iron core to be thrown to the left. By the action of the pivot lever the pinion is forced to the right to engage with the flywheel ring gear. Simultaneously the electrical contacts are bridged and the starter motor turns

Fuel should bubble out without entrained air. Don’t be afraid to try Easy Start in small doses.

It can also sometimes be useful to warm the inlet manifold with a hot air gun.

Ultimately it may have to be acknowledged that the engine is not going to start.

Removal of the injector(s) will enable the use of a borescope, cheap ones linking to mobile phones being widely available, which can examine pistons and bores for serious damage.

Further work could include checking that timing is correct, that injector pump and injectors function correctly and removal of the cylinder head.

But these are beyond the scope of a preliminary inspection and this article.

Pre-engaged starter motors

Pre-engaged starters are designed so that the pinion is engaged with the ring gear on the flywheel before the motor begins to turn.

The pinion then needs to disengage once the engine is running, otherwise the motor would run at very high speeds and destroy itself.

The engaged and disengaged positions of the solenoid shaft and pinion are shown in the two diagrams (above).

The solenoid consists of a coil that is electrically energised through its own terminal by the starter button or key.

In modern starter motors the solenoid terminal is usually a spade type on the end of the solenoid, unlike the old version shown in the photographs where it is a screwed terminal on the side.

Energising the coil drives a soft iron core in the direction away from the starter pinion.

An elderly starter motor showing the electrical connections. The terminal with its nut and washer are connected to the positive terminal of the battery. The terminal without the nut connects to the energising wire to the motor. The wire can corrode and crumble on marine motors. The solenoid terminal is normally a spade type on modern starters. Credit: Vyv Cox

The end of the coil nearest to the pinion is connected to a pivoted lever that forces the pinion assembly into engagement with the ring gear on the flywheel.

On the other end of the core is a brass disc.

As the core reaches the end of its travel the disc bridges two electrical contacts in the solenoid casing, causing current to flow into the motor commutator, turning the motor.

On the motor shown (above) the two heavy terminals, one from the battery and the other into the motor, are clearly visible.

This is not the case with more modern motors in which the terminal attached to the cable into the motor is hidden.

Enjoyed reading How do I tell if an old boat engine is beyond repair?

A subscription to Practical Boat Owner magazine costs around 40% less than the cover price.

Print and digital editions are available through Magazines Direct – where you can also find the latest deals.

PBO is packed with information to help you get the most from boat ownership – whether sail or power.

-

-

-

- Take your DIY skills to the next level with trusted advice on boat maintenance and repairs

- Impartial in-depth gear reviews

- Practical cruising tips for making the most of your time afloat

-

-