A persistent engine coolant leak in a Volvo Penta 2040 was eventually traced to a source most sailors overlook. Vyv Cox shares how he diagnosed the problem and made a fix

Liveaboards Paul and Nicky of the yacht Carmel were experiencing problems with their Volvo Penta 2040, the coolant circuit of which appeared to be suffering persistent airlocks. The symptoms were an engine coolant leak – coolant was being spat out of the engine at a considerable rate, litres of blue water were being found in the bilge at various times.

When the pressure cap was released, the heat exchanger was always full to overflowing. Although Paul had done everything possible to ensure that all air had been expelled from the coolant circuit, it still appeared that air was somehow blowing the coolant out.

Relevant facts in the case were that the filler cap was at the highest point in the system, that there was a calorifier that had previously been leaking but was now repaired and tested, and that the whole circuit had been bled through repeatedly.

Diagnosing an engine coolant leak: Not the usual suspect

A similar problem with Volvo engines has been discussed several times on PBO’s Reader to Reader internet forum. The rubber caps at the ends of the heat exchanger are difficult to fit properly, with the result that if any pressure builds up in the raw water system, seawater can pass the seals and enter the coolant.

To achieve such a pressure, which theoretically only needs to be just above atmospheric, there must be a blockage downstream of the heat exchanger. This is often provided by salt encrustations in the exhaust manifold, where the seawater is injected for discharge overboard.

Several forum responders, including myself, suggested this might be the cause of their problem, but Paul replied the whole manifold had recently been removed and cleaned, and a new thermostat added at the same time – so no salt blockage.

Other forum suggestions included faults such as a cut in a hose in the calorifier feed, absence of a coolant expansion vessel, a failed cylinder head gasket, a faulty thermostat or a blocked anti-siphon valve. It seemed to me, however, that none of these theories completely satisfied the observations.

At this point, another relevant fact emerged: water was overflowing from the engine even when it wasn’t running.

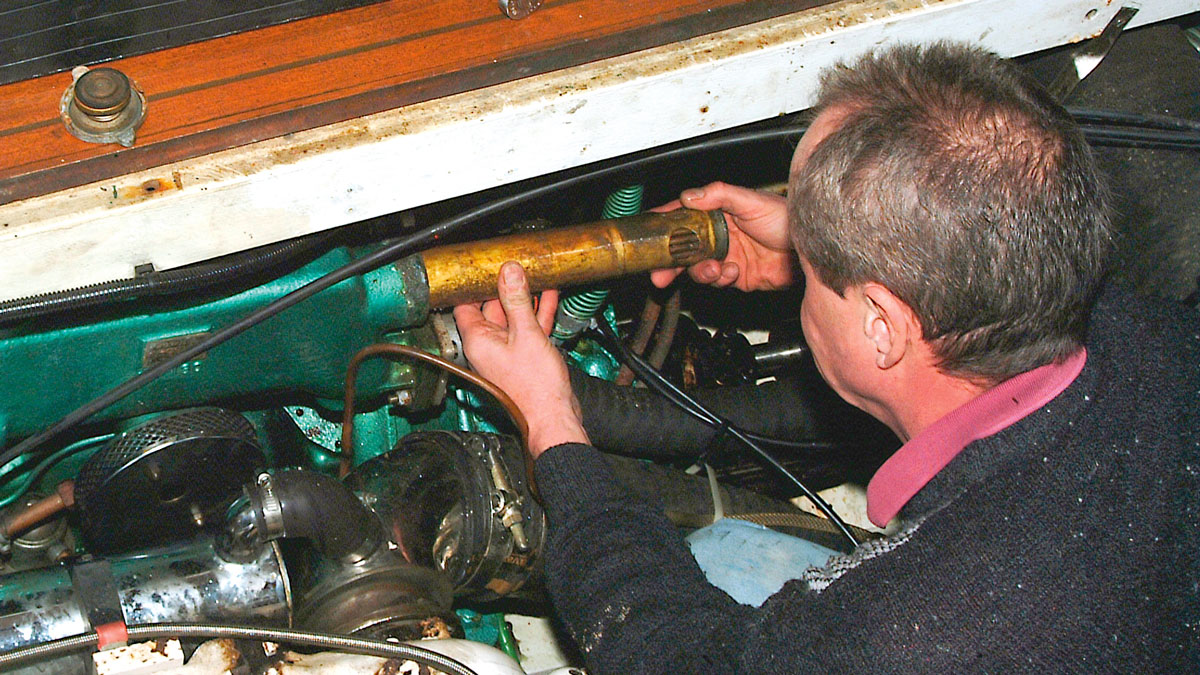

It turned out that Nicky and Paul were anchored only about five miles away from me, so we arranged for them to visit the marina where I was currently moored so I could give them a hand in checking things over.

Calorifier culprit?

A very tidy installation of the calorifier, with no obvious leaks or other apparent problem from here. Credit: Vyv Cox

It seemed to me that the cause had to be a perforation in the heating coil of the calorifier, allowing water to pressurise the engine coolant circuit until it overflowed. The first thing I checked was that this was possible from a relative pressure point of view.

The engine pressure cap was rated 75kPa (just over 10psi). Most yacht domestic water pumps are rated at more than 20psi, with some considerably higher. This showed that a leak of fresh water into the coolant was possible, rather than the reverse.

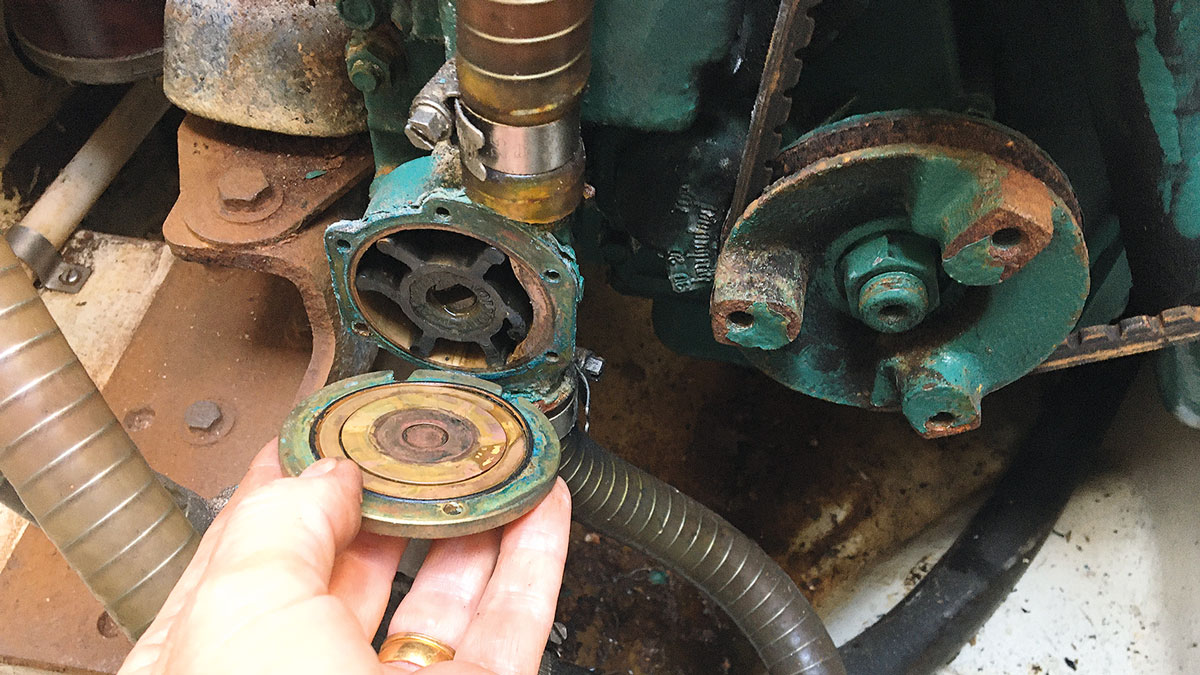

Paul and I set up a test to prove whether this was indeed happening. After turning off the domestic water pump, we removed the two calorifier hoses from the engine, then bridged the open nozzles on the engine with a short length of new hose (the red hose in the photo below).

We pushed the two ends of the calorifier hoses into a cut-down water bottle, turned the domestic pump back on and retired to the cockpit for a beer.

By the time we had drunk a can each, the bottle was nearly half-full of pale greeny-blue water. We had identified the source: definitely a leak in the calorifier coil.

The test set-up: The two calorifier hoses in the cut-down collection bottle.

The red hose bridges the two engine nozzles, allowing the motor to be used.

At the right is the rubber cap of the heat exchanger. Credit: Vyv Cox

Paul explained the recent repair and testing of the calorifier involved pressurising the coil while inspecting the repairs to the external nozzles using soapy water. Of course, nobody thought to check that air was coming out inside the vessel!

As a final check, Paul ran the engine for a short time and monitored it over the next 24 hours. No more water emerged – problem identified!

To allow the boat’s fresh water to be used, we joined the two ends of the calorifier hoses together with a short length of tubing. Once the pressure in here reaches that of the domestic water, no more leaks should take place.

All that remained was for Paul to see if his three-year-old calorifier could be replaced under guarantee. In the meantime, Nicky resigned herself to cold showers for a while.

How to winterise a boat engine

Engineer Stu Davies explains the steps you should take to make sure your boat’s engine is protected over the winter…

5 top causes of boat engine failure – and how to avoid them

Jake Kavanagh talks to Sea Start marine engineer Nick Eales about how to avoid the five major causes of an…

How to service a marine engine cooling system

Is your boat's engine beginning to run hotter than normal? It may be time to service the cooling system, suggests…

Fixing boat engine cooling system problems

Stu Davies solves niggly Volvo Penta 2030 engine cooling problems

Want to read more articles like Engine coolant leak: how to make a temporary fix?

A subscription to Practical Boat Owner magazine costs around 40% less than the cover price.

Print and digital editions are available through Magazines Direct – where you can also find the latest deals.

PBO is packed with information to help you get the most from boat ownership – whether sail or power.

-

-

-

- Take your DIY skills to the next level with trusted advice on boat maintenance and repairs

- Impartial, in-depth gear reviews

- Practical cruising tips for making the most of your time afloat

-

-

Follow us on Facebook, Instagram, TikTok and Twitter