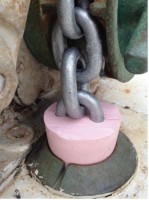

Derek Fairley makes a bung for his boat's navel pipe with the aid of some silicone rubber and a Choc Dips pot

My 85-year-old Hillyard gaff cutter Waif has a manual windlass, with the anchor chain led below through a 2in navel pipe in her foredeck.

The anchor locker is in the bow, directly below the pipe, but there is no external drain, so water entering through the pipe goes to the bilge. In anything more than very moderate seas, a great deal of seawater can (and does!) enter by this route. I needed a way to plug the navel pipe when at sea,  but without removing the anchor chain. My solution was to make a split silicone rubber bung, as follows.

but without removing the anchor chain. My solution was to make a split silicone rubber bung, as follows.

Firstly, I needed a suitable plastic mould, and a KP Choc Dips pot was perfect. I cut the base out of the pot, sealed the top with duct tape and suspended an offcut of 10mm anchor chain inside the inverted mould. After adjusting the chain height so that it just touched the duct tape, I filled the mould with Polycraft high-strength silicone rubber, supplied by MB Fibreglass in Belfast. After curing it for 24 hours, I removed the mould to reveal a tapered rubber bung formed around the chain. Using a craft knife,

I carefully split the bung into two halves and cut 1cm from the larger end. The finished split bung fits snugly around the chain and into the navel pipe, giving a virtually watertight seal that can be easily removed for anchoring.

I carefully split the bung into two halves and cut 1cm from the larger end. The finished split bung fits snugly around the chain and into the navel pipe, giving a virtually watertight seal that can be easily removed for anchoring.

Total cost of the project was 50p for the mould (with free Choc Dips) and £15 for the silicone rubber.

Derek Fairley

We pay at least £30 for each tip published in PBO! Send us yours today…