Sam Longley fixes his Portland plotter

In a mad fit of inspiration, I decided that after 50 years of cruising I needed to take my Yachtmaster offshore exam. So out came the Portland plotter in earnest.

In normal circumstances, on a bouncing boat ‘near enough is good enough’ but in a classroom, under the glare of the instructor, nothing other than ‘spot on’ will do.

The trouble is that although I have four Portland plotters they are all stiff and all want to jump 3° just at that vital moment when you only want 1°.

So I decided to repair the thing. I started with generous dose of oil. No good. I then held the handle part in my lathe and spun the dial at 1,000rpm for a minute, thinking I could wear the disc on the spindle a bit. No use!

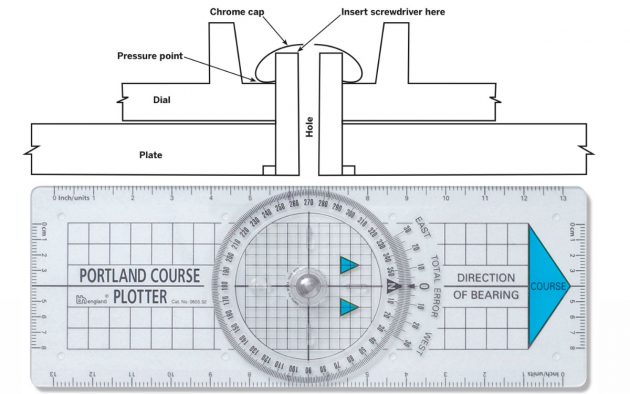

Finally, intending to put a small bolt through, I drilled a 3mm hole from the back right through the spindle. I inserted an electrical screwdriver under the chrome captive cap to lever it off, but in practice this was not needed. I just worked it up slightly all round, gently, with the tip of the screwdriver.

Success! The levering reduced the pressure the cap was putting on the dial and I can now plot with ease. It did damage the cap a little but, hey, it works.

Originally published in PBO Oct19