The term common rail diesel has nothing much to do with locomotives but refers to the engine’s injection system, which is built around a high-pressure fuel rail as opposed to a low-pressure fuel pump feeding unit injectors, which is what you get on conventional engines.

Common rail diesel engines have been used in boats and trains since the 1940s, and were given more development for road vehicles in the late 1960s. However, not many smaller yachts are fitted with them.

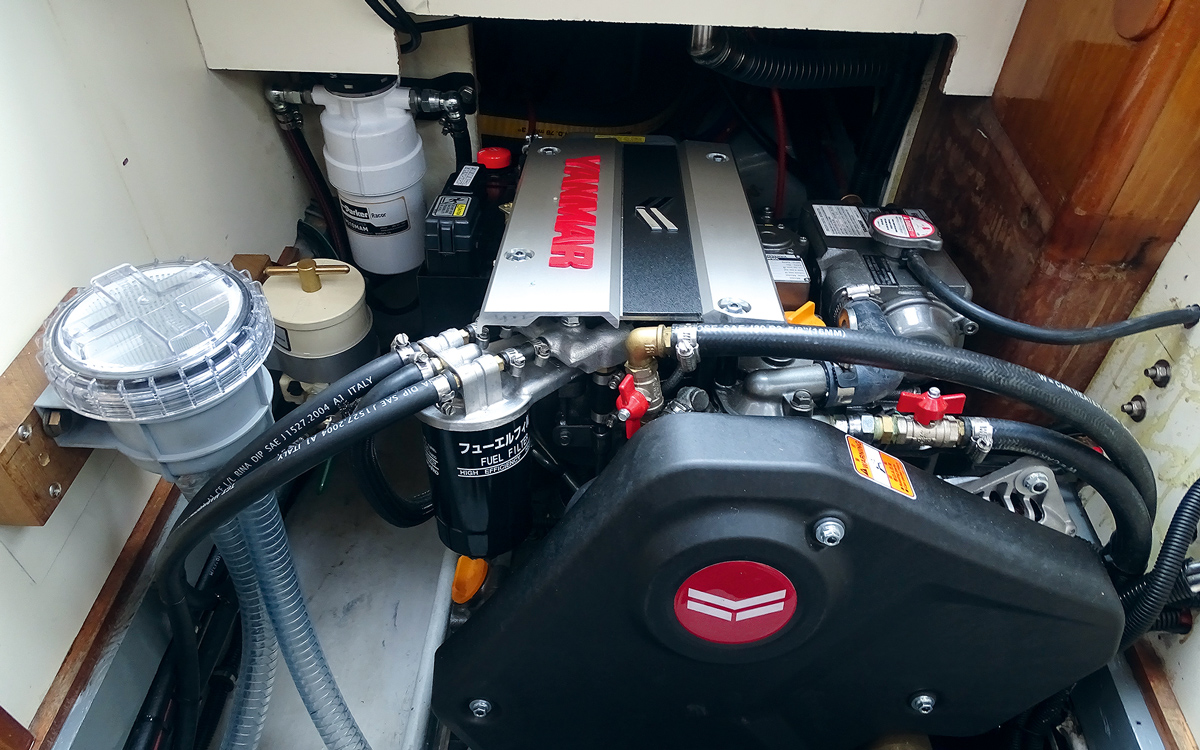

The 4-stroke Yanmar 3JH40 is the world’s smallest common rail inboard marine diesel engine in terms of displacement, dimensions, and weight.

The 3-cylinder water-cooled engine has an output of close to 40hp at 3,000rpm and is aimed at smaller leisure boats, specifically monohulls and catamarans up to 45ft, small motorboats and light duty commercial craft.

Article continues below…

Engine health check: 6 steps to make sure your diesel is in fine fettle

An idea struck me when I ordered an oil analysis for Merlot, my lockdown project boat. Routine health checks are…

How to install a common rail diesel engine on a boat

Late evening turned to night as Pippin fought adverse tides off Corbière, hard on the wind, her old Yanmar straining…

PBO engine expert Stu Davies comments: “The ‘common rail’ in diesel engine context, is a tube/container fixed to the engine that is fed by a very high pressure fuel pump that delivers up to 30,000psi.

“The common rail acts as a reservoir for the high pressure fuel, which feeds the injectors which are all connected commonly to the rail. The injectors are basically a pop-off valve that is controlled by a computer.

“The computer says ‘open’ at the optimum moment and the very high pressure fuel then is allowed to pass into the appropriate combustion chamber in the engine where it ignites to provide the gas, which pushes the pistons down.

Stu Davies has a background in engineering in the coal and oil industries

“It is a very efficient, simple system compared with the multi-piston injector pumps that have been used for years. However the controller is a computer, of which more in a moment.

“The common rail system as we know it today has only been used mainstream in our vehicles comparatively recently. The reference to common rail engines in the 1960s is probably referring to 2-stroke Detroit Diesels and their ilk.

“They used a hybrid system with a fairly low pressure common rail to feed mechanically driven injector pumps in the cylinder head.

“I understand why our boat engine manufacturers are going common rail; they are more efficient, and easily controlled by electronics to produce optimum combustion effects.

“However the devil is always in the details, in this case the electronics. Many of us have experienced the dreaded engine management light coming on in our cars and the sinking feeling as the engine goes into limp mode. Then, of course, the expensive visit to the main dealer to plug in the diagnostic computer.

“Our engines live in a very hostile environment and my question is, are the electronics ‘hardened’ enough to withstand these conditions and has thought been given to how to fix them if issues arise mid-ocean?

“Going into limp mode in the Channel as we cross the shipping lanes would be my fear. Our old fashioned diesel engines can be fixed with simple hand tools that we all carry. Visiting the dealer to plug in a computer to fix it is not an option.

“I am aware from doing some work on the Volvo Penta ‘black box’ on the D-series engines (a fault with the MDI Unit, Part No 23231607, which caused engine starting and stopping issues) how challenging electronic engine stuff can be.

“I’m impressed by what John Willis has done, however, and hope he keeps us updated on how his project works out.”

Why not subscribe today?

This feature appeared in the November 2021 edition of Practical Boat Owner. For more articles like this, including DIY, money-saving advice, great boat projects, expert tips and ways to improve your boat’s performance, take out a magazine subscription to Britain’s best-selling boating magazine.

Subscribe, or make a gift for someone else, and you’ll always save at least 30% compared to newsstand prices.

See the latest PBO subscription deals on magazinesdirect.com