Peter Fildes builds a circuit to effectively charge his batteries from his outboard motor’s lighting coil

Lighting coils are often found fitted to the flywheels of cord start outboard motors. They produce alternating current (AC), and are primarily designed to power the navigation lights of small open boats without batteries. The power from these systems is deliberately limited to prevent the light bulbs from blowing.

If you have one of these and want to charge a battery, the charger sold to you by the dealer will often be a single diode, which simply cuts out half the alternating current to give a pulsed direct current with half the available power.

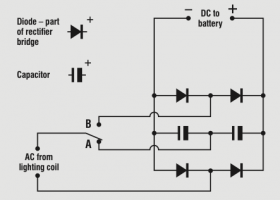

The first part of a solution therefore lies with a bridge rectifier and capacitor to make use of all the available current. This will provide more power, but the voltage is still not high enough to effectively charge a battery. To solve this problem I’ve devised a simple circuit which costs less than £6 to build.

By connecting a pair of series capacitors across the DC output of the bridge rectifier, and inserting a switch in one side of the AC input that allows you to switch it between the rectifier input and the centre connection to the pair of capacitors, you give yourself the option to convert the rectifier into a voltage doubler. I used a 25A, 35V bridge rectifier and 35V, 4.7mF capacitors, but any high capacitance value will do – the higher the better.

With the switch in position B (see diagram) the circuit will supply about 12.4V, depending on how fast the motor is driven. On sailing boats this is rarely over 75% of maximum revs (my Tohatsu 6 will give 8A at this speed). This is enough if the engine is always in use, but if battery power is required without the engine then the charge is utterly inadequate to keep the battery topped up. Lights, an autopilot, and electric reefing require a fully charged battery that stands

at 13.2V, and over 14V while on charge.

In position A the circuit will produce a voltage around double that of the straightforward rectifier. Of course nothing is free and the lighting coil is still producing the same power, so the available current is halved – around 4A from my Tohatsu 6. However, this is perfectly adequate for gentle battery charging.

Ideally the circuit should be followed by a voltage regulator to keep the voltage down to around 14.4V, but lead-acid batteries are tolerant of quite high voltages when charging so I just keep an eye on my voltmeter and switch from A to B if the voltage gets uncomfortably high (say over 16V). If you do decide to add a voltage regulator, several good circuits are available online.

Ideally the circuit should be followed by a voltage regulator to keep the voltage down to around 14.4V, but lead-acid batteries are tolerant of quite high voltages when charging so I just keep an eye on my voltmeter and switch from A to B if the voltage gets uncomfortably high (say over 16V). If you do decide to add a voltage regulator, several good circuits are available online.

You will note that no soldering is necessary, and it’s a good idea to buy your crimp tags from a motor trade supplier – they’re much cheaper than the little plastic packets of 10 from hardware superstores.

An alternative approach would be to fit a 1:1.5, 100W transformer on the output of the lighting coil before rectifying the voltage, but I have been unable to find one at any half-sensible price. If anyone knows of such a thing, I’d love to know!

Peter Fildes

We pay at least £30 for every practical project published in PBO. Send us yours today!